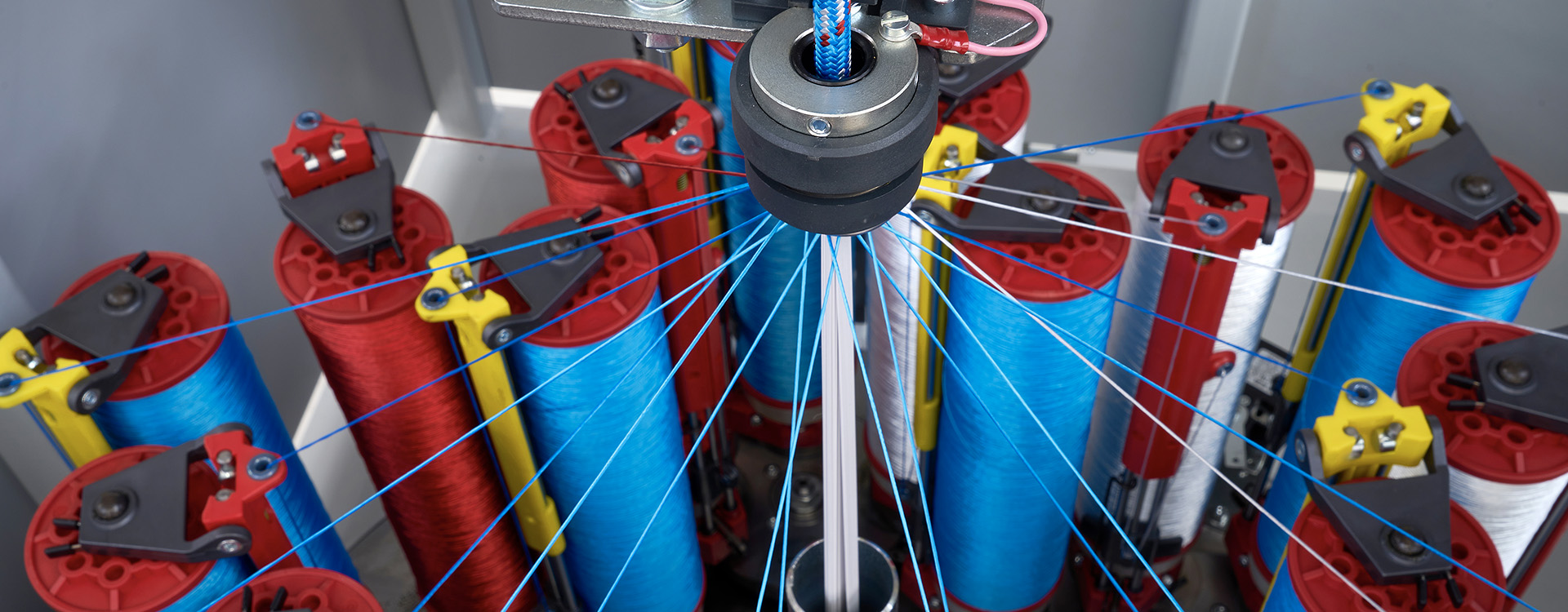

Braided Ropes & Cords

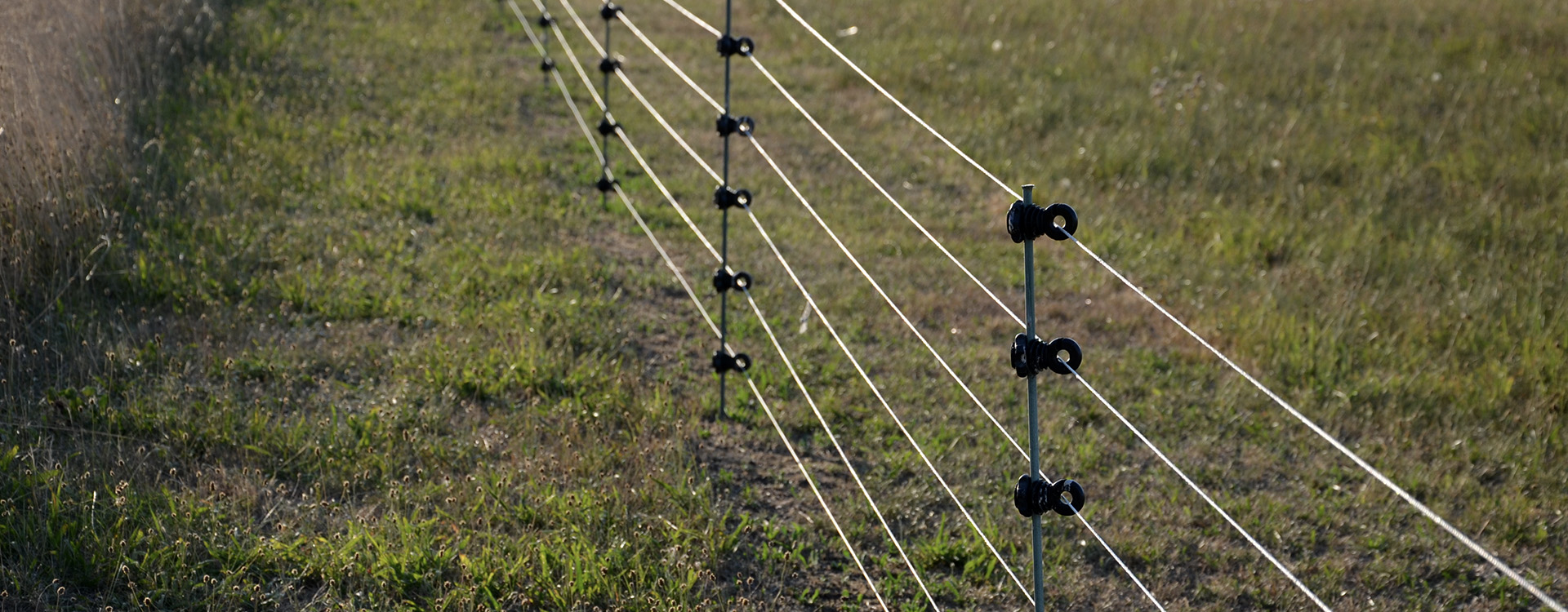

Braiding encompasses many types, sectors, and forms. Ratera braiding machines allow for the production of a wide range of applications, from small cords for agriculture or decoration, to safety ropes or nets.

Applications

- Security ropes (construction, arboriculture…)

- Electric fences for livestock

- Agriculture twines

- Dog leashes

- Paracord

- Nets

- Hardware ropes

- Twines

Materials

- Polypropylene

- Polyethylene

- Poliéster

- High Modulus Polyethylene (HMPE)

- Nylon / Polyamide

Videos

We customize our machines to depending on your needs

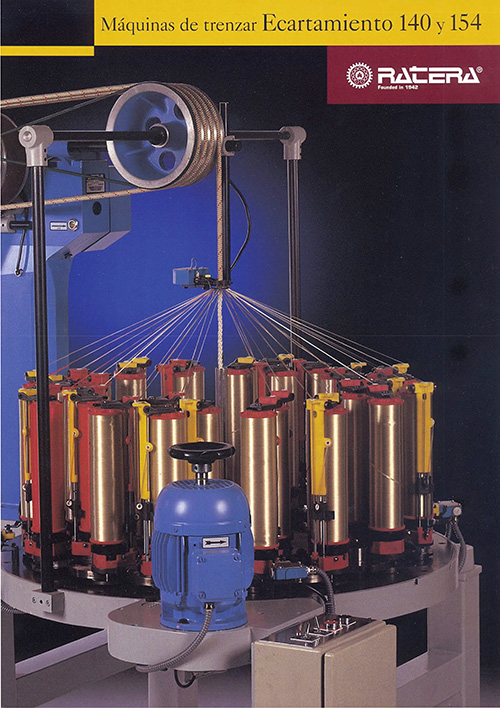

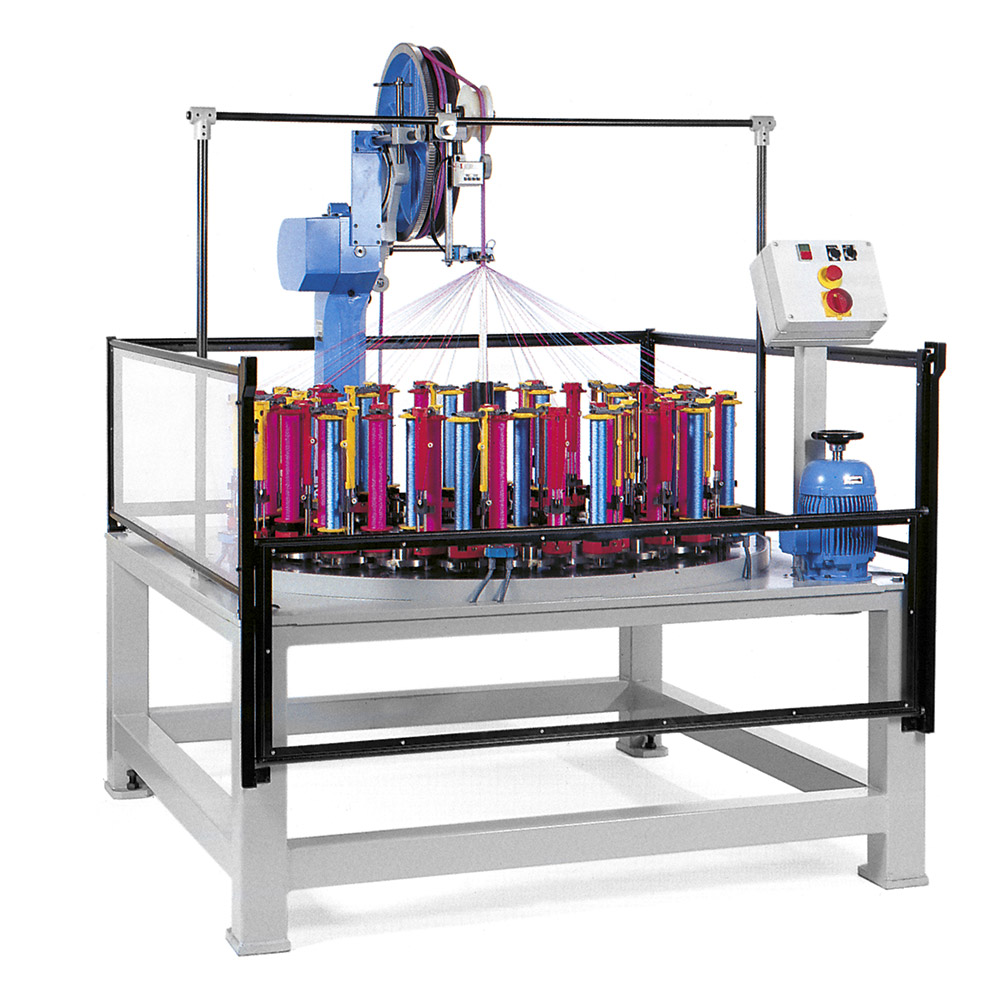

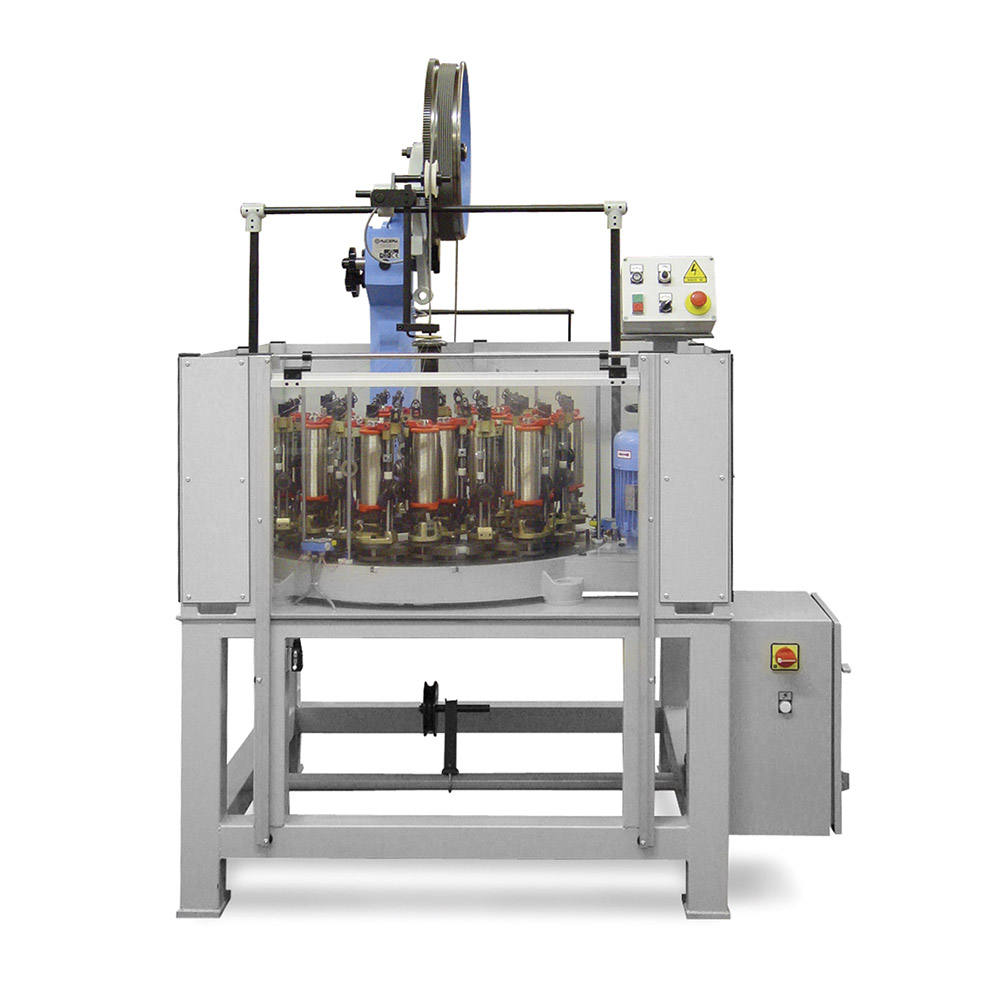

Ratera customizes machinery according to the product to be manufactured.

Some of the main parameters to select are:

- Number of carriers: The carriers is the moving part where the bobbin with thread to be braided is loaded. There are braiders from 3 to 144 carriers, with 16 being the most popular, followed by 12, 24, and 32 carriers.

- Gauge: diameter in mm of the horn gear. This will determine the capacity of the bobbins of the carriers that make up the braider. From E-80 for fine braids, through the E115 braider which offers the best speed/quality ratio on the market, to the E-208, with a very high bobbin capacity and allows braiding under high tension.

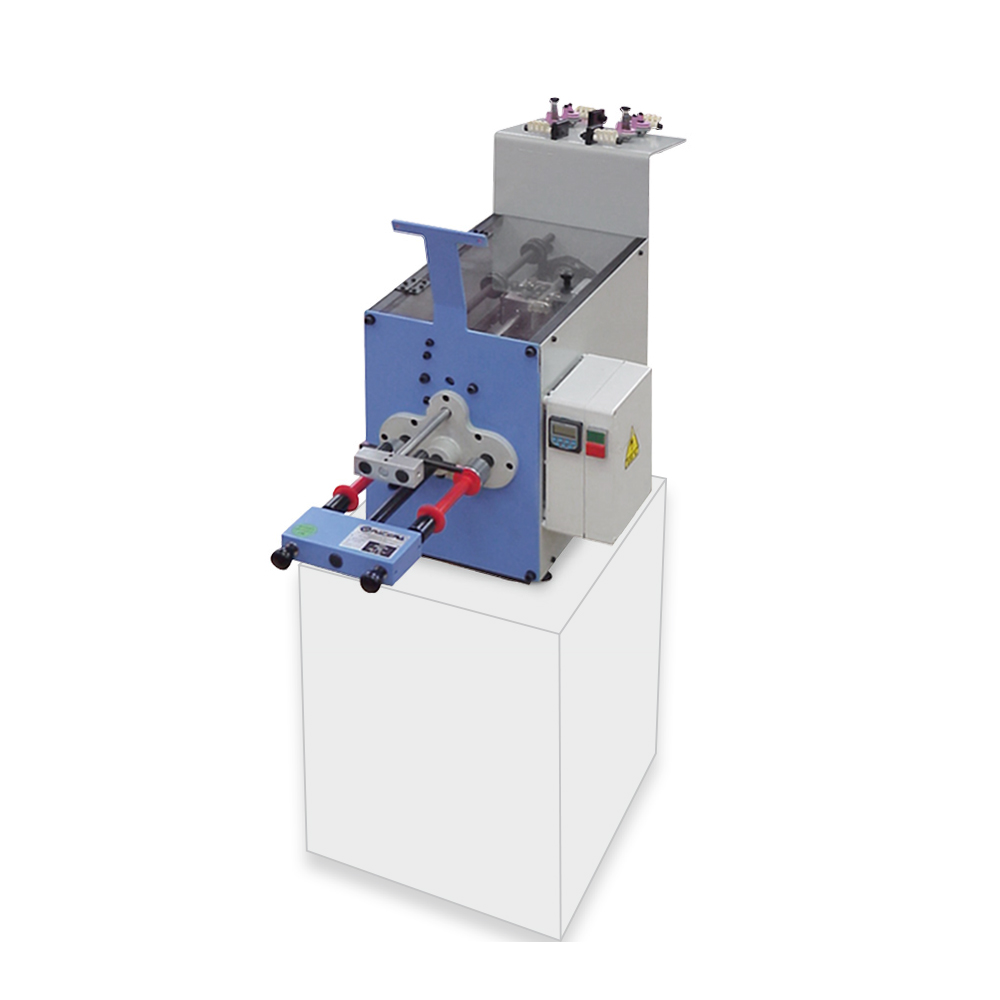

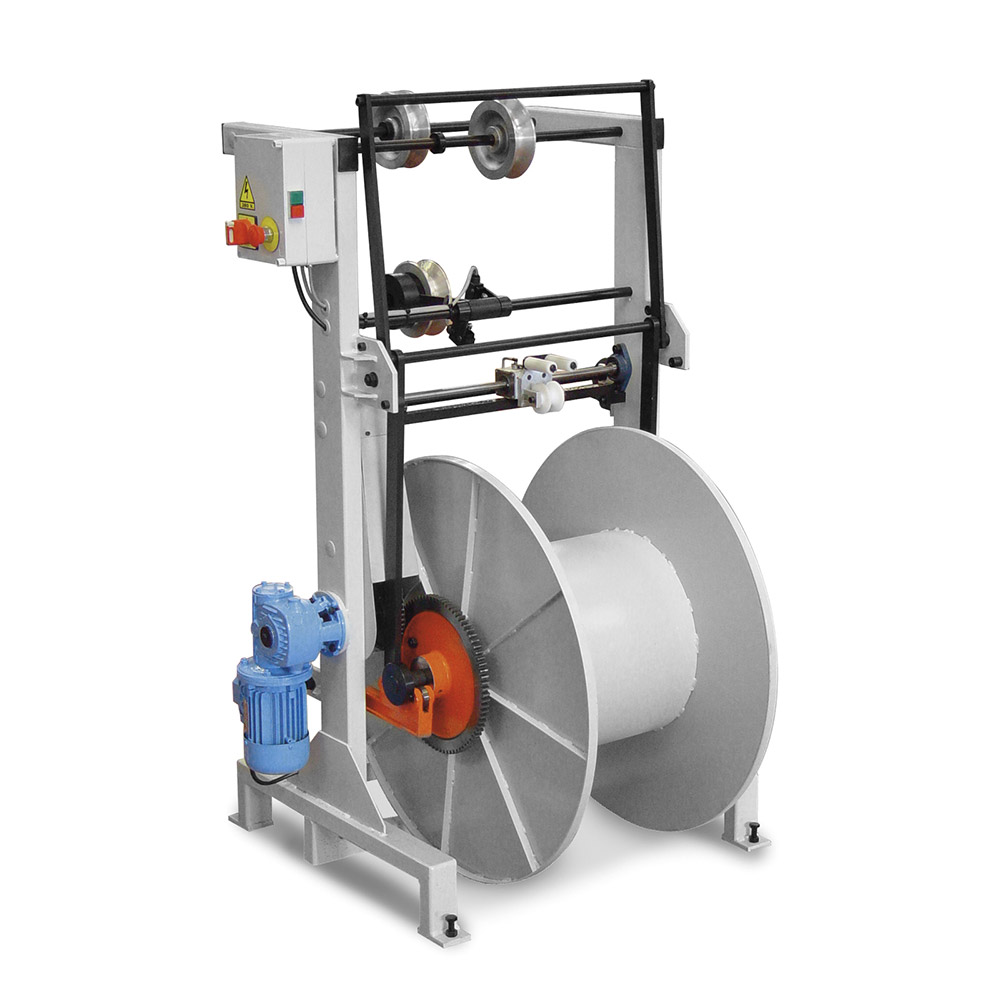

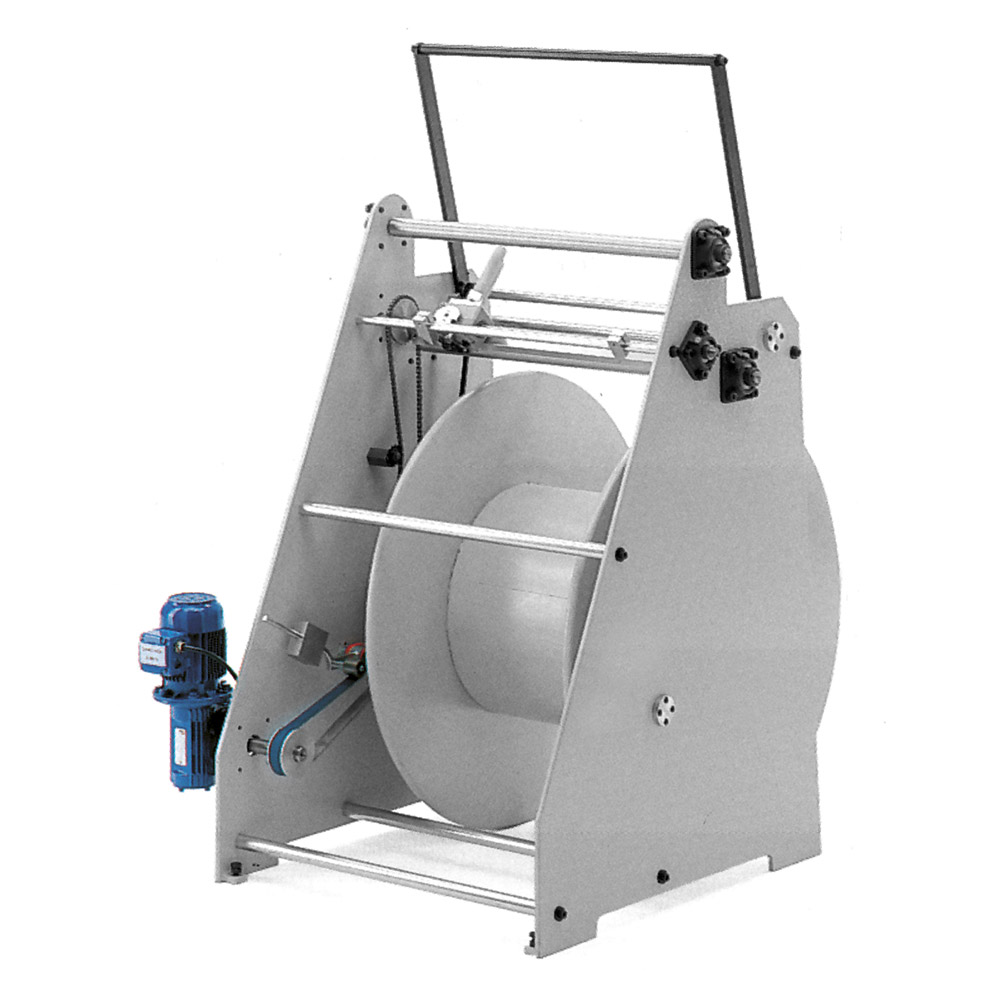

- Take-off system: Wheels with a calender, Multiple wheel take-off system, folder for braid collection, etc.

- Core of the braid. Referring to the core of the rope (whether elastic or rigid), Ratera adapts the braider with the necessary devices to cover the core, such as presence sensors, tensioners, guide pulleys, or mechanisms to tighten the elastic bands.

- Protections according to CE standards and/or national standards of each country.