Sutures & Medical Braids

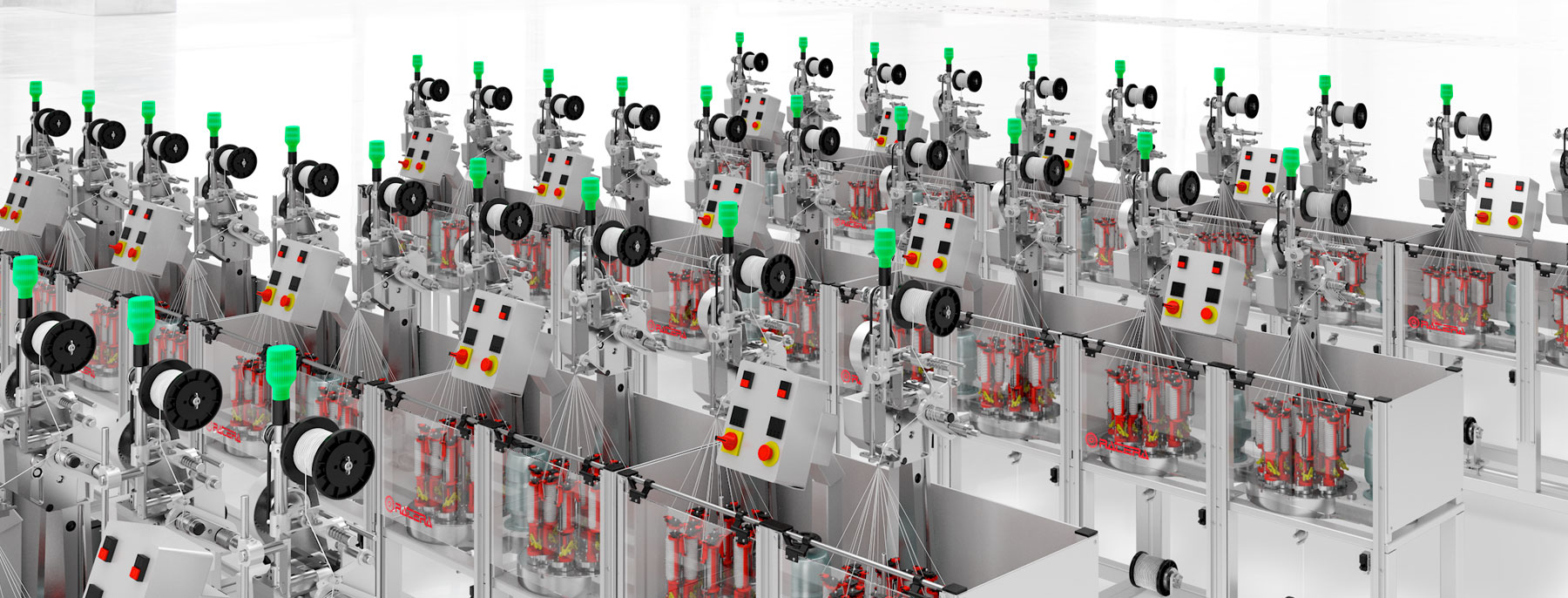

Latest technology in braiding for the medical sector

Ratera machines apply to a broad range of medical applications, specializing in sutures of all kinds to include bio-absorbable and non-absorbable. We are well versed in the finest deniers for precise applications, to the heavier deniers for more robust requirements, such as those found in veterinary medicine.

Suture Braiding Specialists

Ratera machines can make several braided constructions (round, flat, hollow braids, elastic, sleeves) covering a broad range of medical applications.

Applications

- Suture (Bio-Absorbable, Non-Absorbable, Veterinarian)

- Metalic hose

- Orthopedic tools

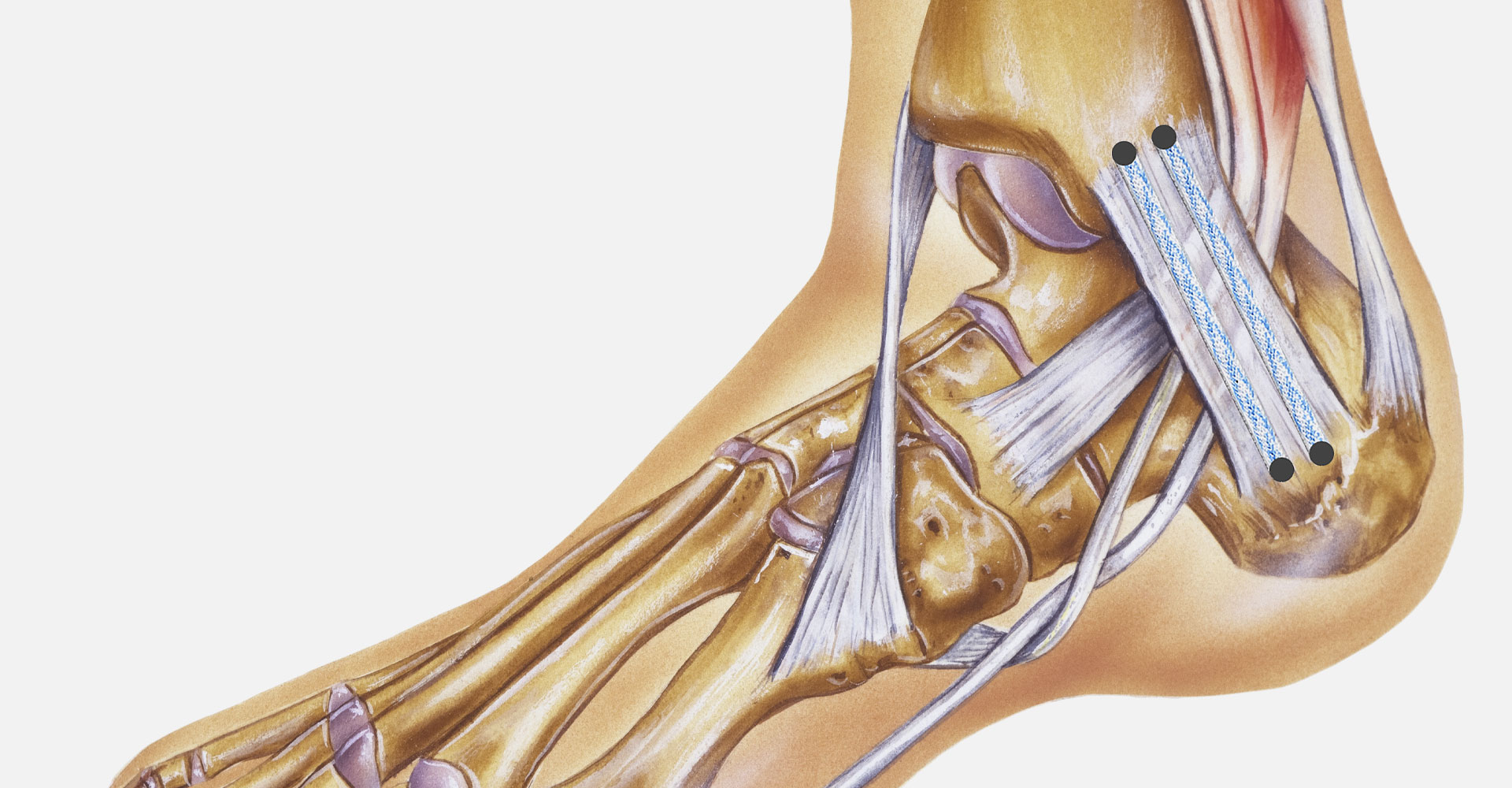

- Tendon repair

- Dental floss

- Conduit reinforcment

- Elastic band for mask

- Braids for ligaments

- Cords

- Cable sleeve

Materials

- Polyethylene (UHMWPE, PET)

- Polyester

- Polypropylene

- Polyamides

- Nylon

- Cotton

- Stainless steel

- Copper

- Alloys

- Fiber glass

- Carbon fiber

Latest technology in braiding for the medical sector

1 Medical braiding machines in detail

16B-E80 · for suture

2 Customized to your needs

16B-E80

Single or double head machines

- For laboratories or start-ups, 1 head can be enough for reaching production.

- For large scale productions, double-head machine offers space and costs saving as well as redundancy.

8B-E80

Single or double motor

- One motor per head for high efficiency and reliability.

- One motor for two heads for cost reduction and space saving

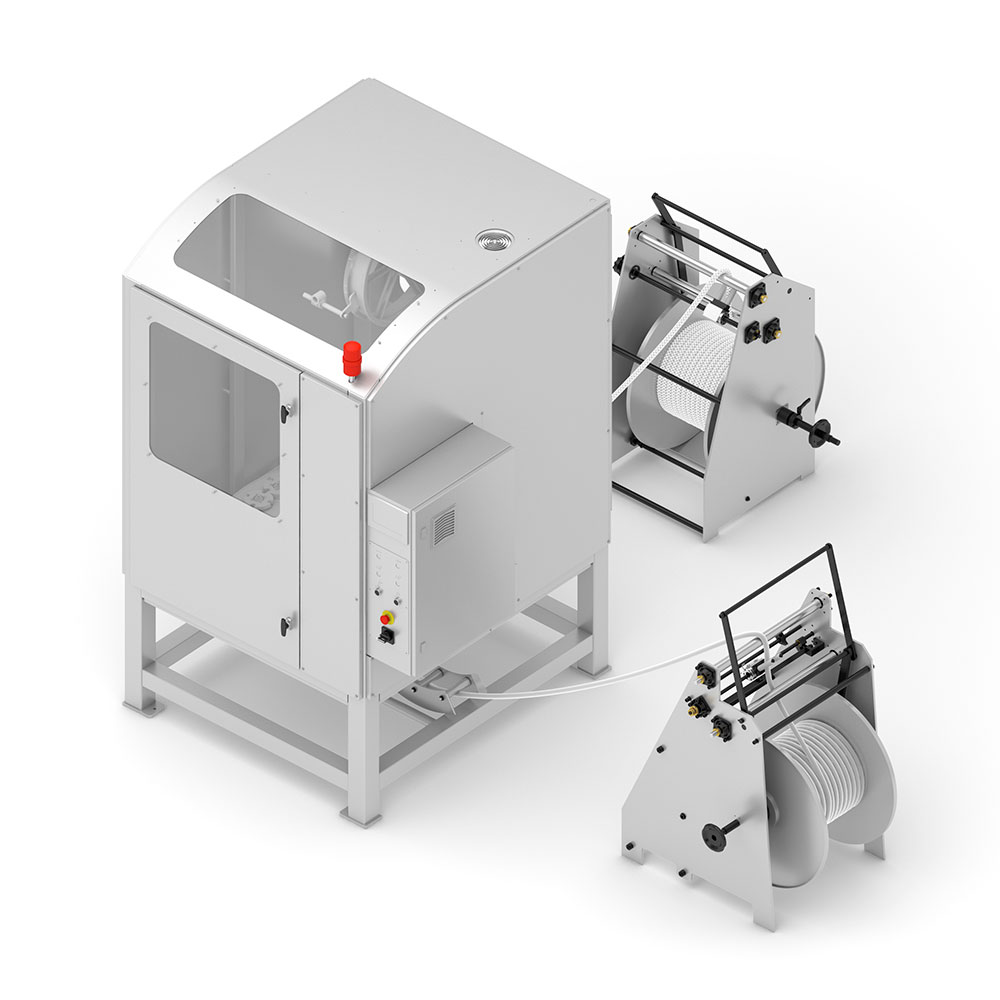

48B-E80

Full protection

- Example of a single head machine with a fully enclosed protection and soundproof.

17B-E80

RATEX system

- Progressive stretching of rubber for elastic braids.

- Adjustable elongation with sprockets.

24B-E115

System Integration

- Ratera supports the customer to integrate feeding creels and independent take-ups with the braiding machine.

3 Highlighted Machines

3 Highlighted Machines

17/120 RFR

Continuous round and flat braid

The 17-120 RFR braider is designed for the manufacture of special products consisting of round braid and flat braid sections, in a continuous manner.

The transitions between both types of braiding are smooth, with no splicing of any kind.

Technology

These are the first generation of Ratera machines to be fitted with servomotors for driving the horngears. This allows the precise and synchronized movements required for this type of braiding.

Connectivity

Includes module that can be connected to your company’s Ethernet. This can be used, if necessary, to add such utilities as software updates and remote monitoring of the machine’s status.

Control

The touch screen is used to set all of the parameters required to produce braids. Stitches, length and speed can be set for production of each round or flat section. These parameters can be saved as programmed tasks. The machine also features a manual mode for wheeldirected movement.

Carriers

The 17-120 RFR machine operates with gauge 80 Ratera carriers. Specially designed for fine products that are mainly used in medical applications. Very easy threading.

4 Winding Machines, the key of a good braid

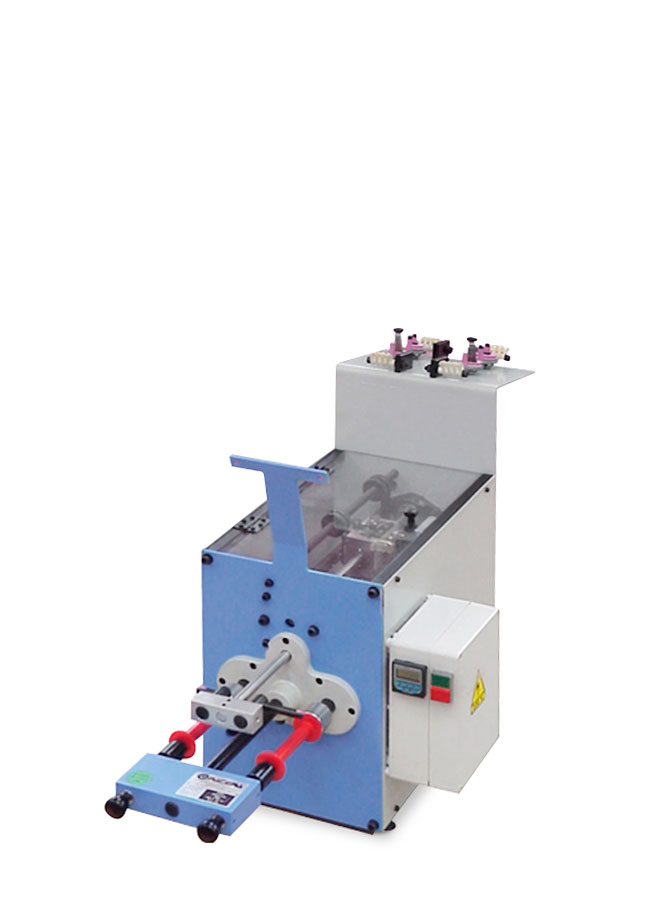

ML-100

Automatic Winding Machine 4 heads

High efficiency and yield