History:

renewal of experience

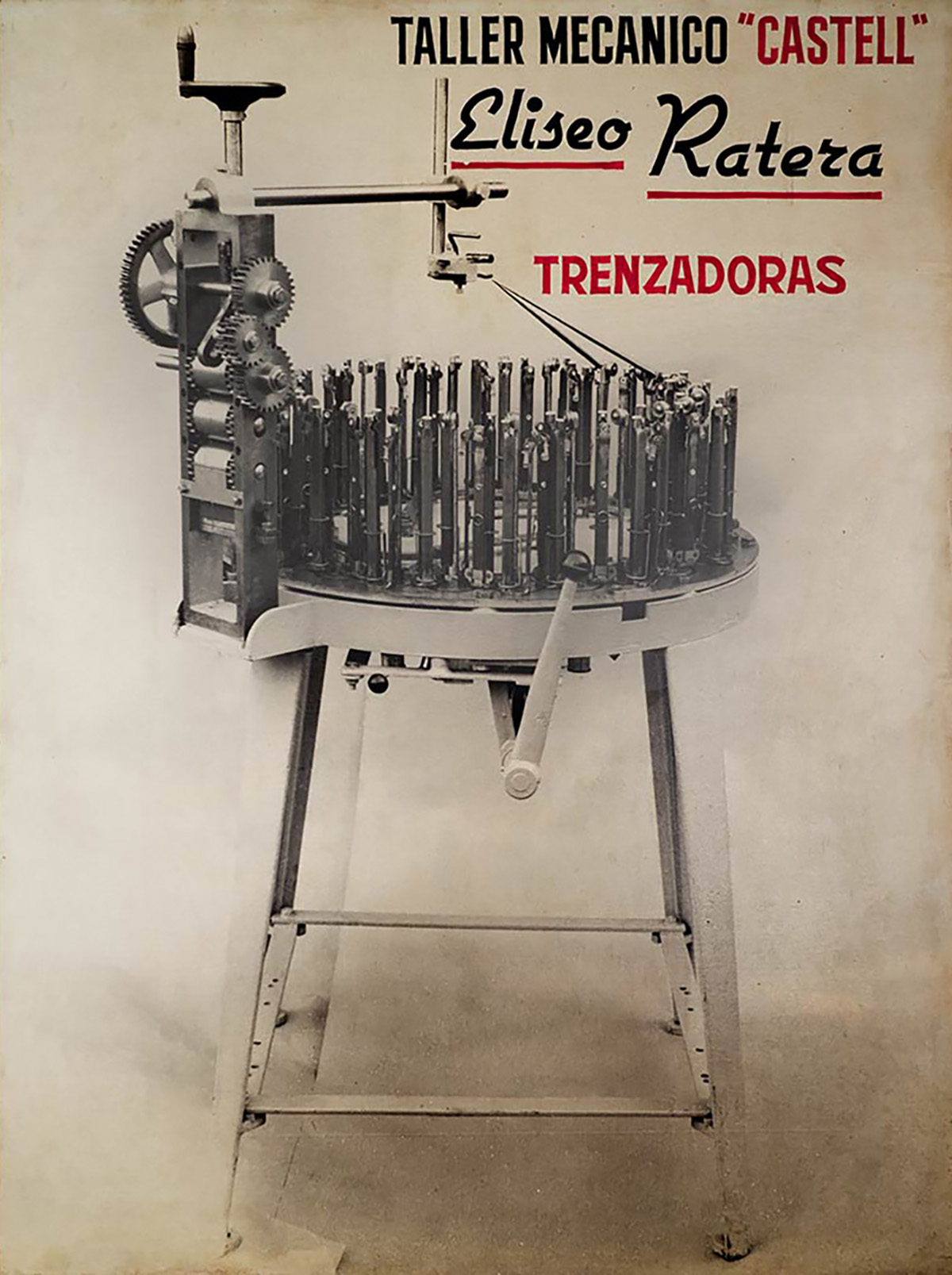

Since 1942, year which the company Ratera was founded, developing an important job in research and technological development in the Braiding industry and its auxiliary machines.

Due to this effort, Ratera has become a leader company in this field exporting all over the world over 120 countries.

R&D:

Technical office

Adaptability

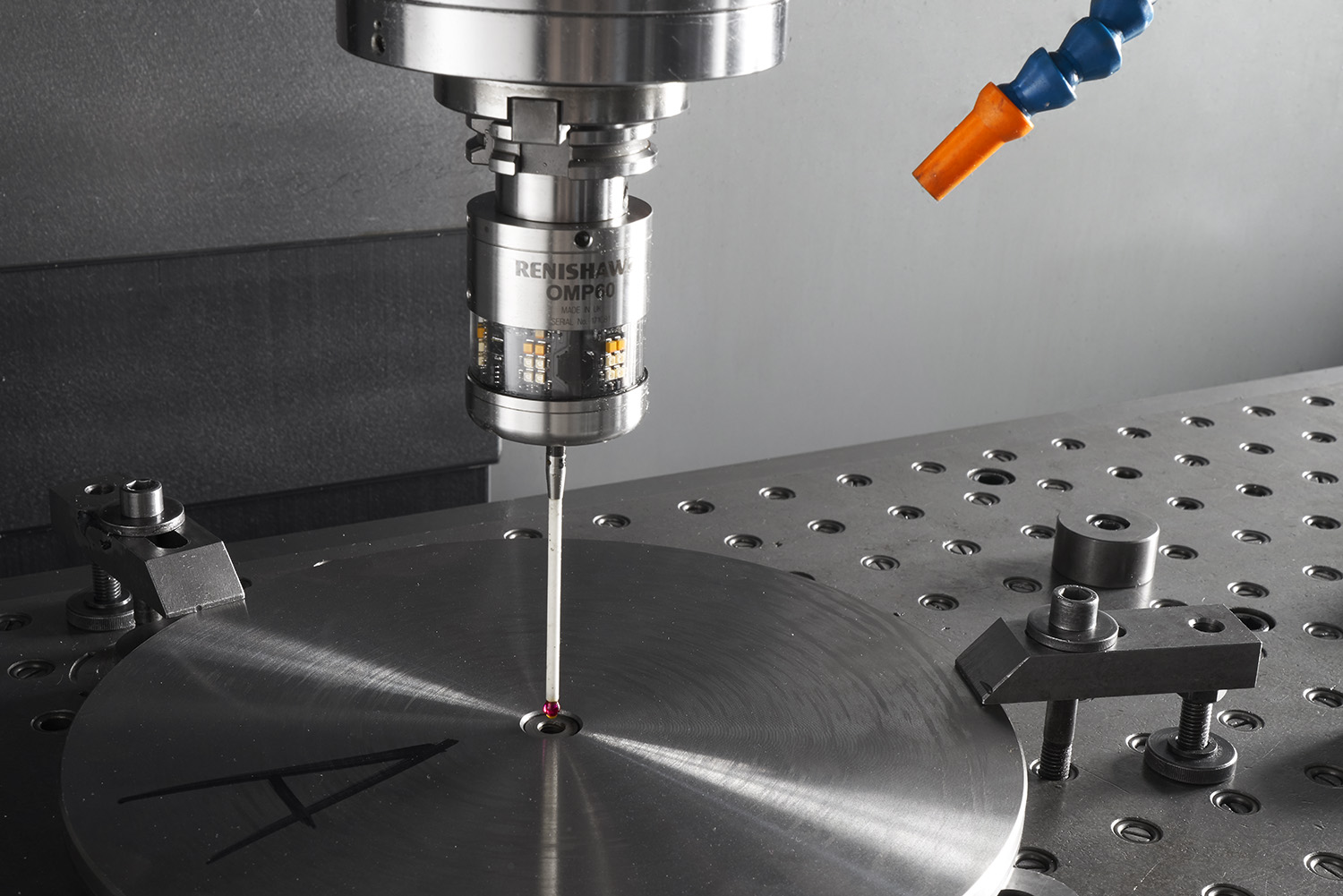

Ratera keeps developing and improving constantly its products combining the highest technology in design using different computerized systems CAD (Computer Assisted Design) and CAM (Computer Assisted Manufacturing)with a deep knowledge in this field and all the requirements in the braiding industry.

Production and assembly:

offering solutions

We are not limited to one product or service. At Ratera we offer a solution. Thanks to the CAE (Computer Assisted Engineering) system, we carry out simulations of measurements, budgets, calculation of structures and finally a production plan.

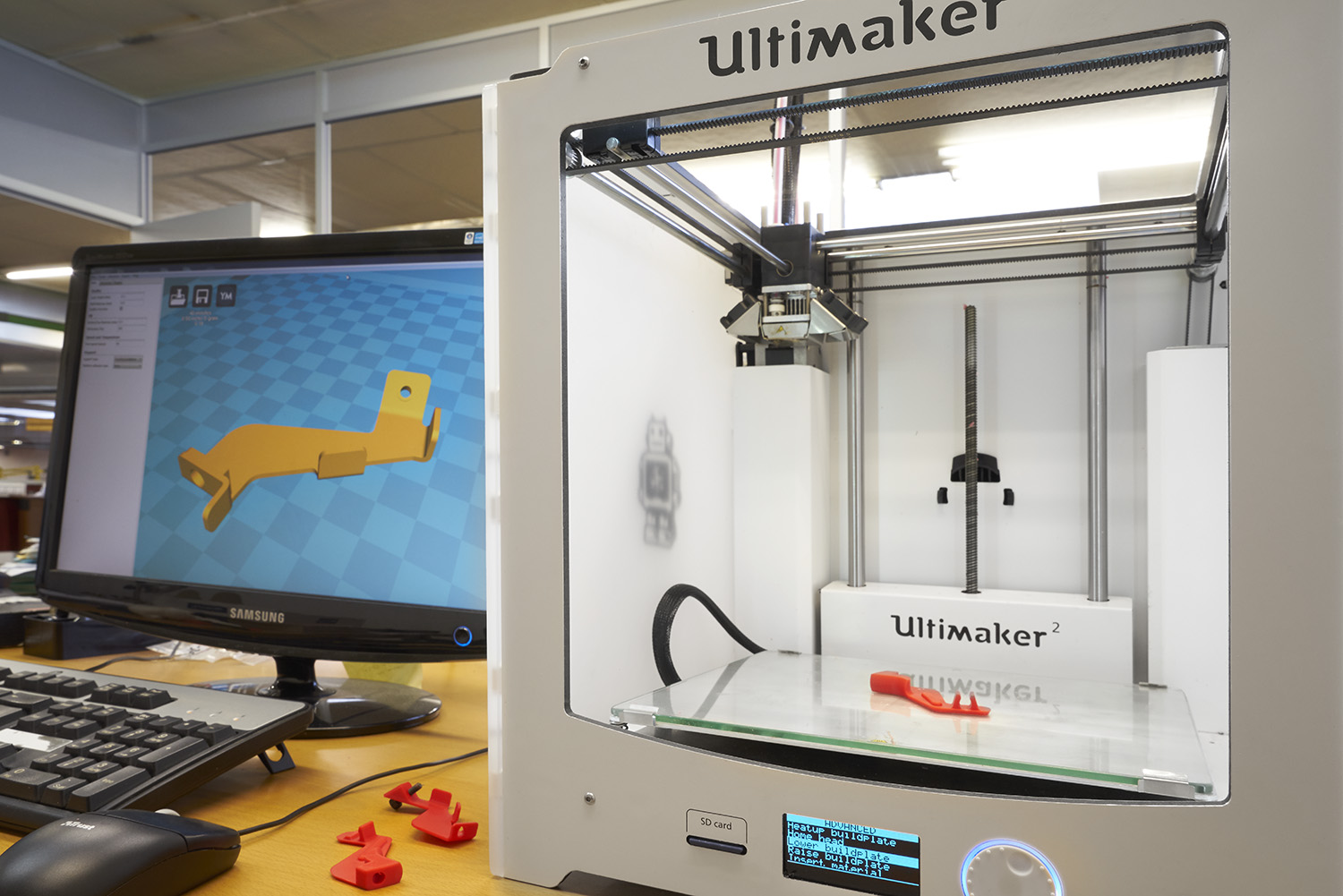

Our 3D printing technology provides great versatility and facilitates production control, adapting to the needs of each client.

Thanks to the Lean Manufacturing implementation process, we obtain an optimal product in a specific location and at a specific time.

A process with flexibility and adaptability to the evolution of the markets.

Expedition

and global logistics

The worldwide size of Ratera is the key of its success: Exporting the 90% of its production to more than 120 countries with a client portfolio of more than 7000 customers.

Producing more than 2,500 machines per year.

Final product

The range of our products covers over 320 different models, Ratera tries to cover all the needs of the braiding industry.

Its versatility allows to adapt its models to each customer requirements in particular.

Quality guarantee

Ratera believes in quality as our cornerstone. This is why we use an integrated system that includes quality management and environmental management in accordance with international regulations.