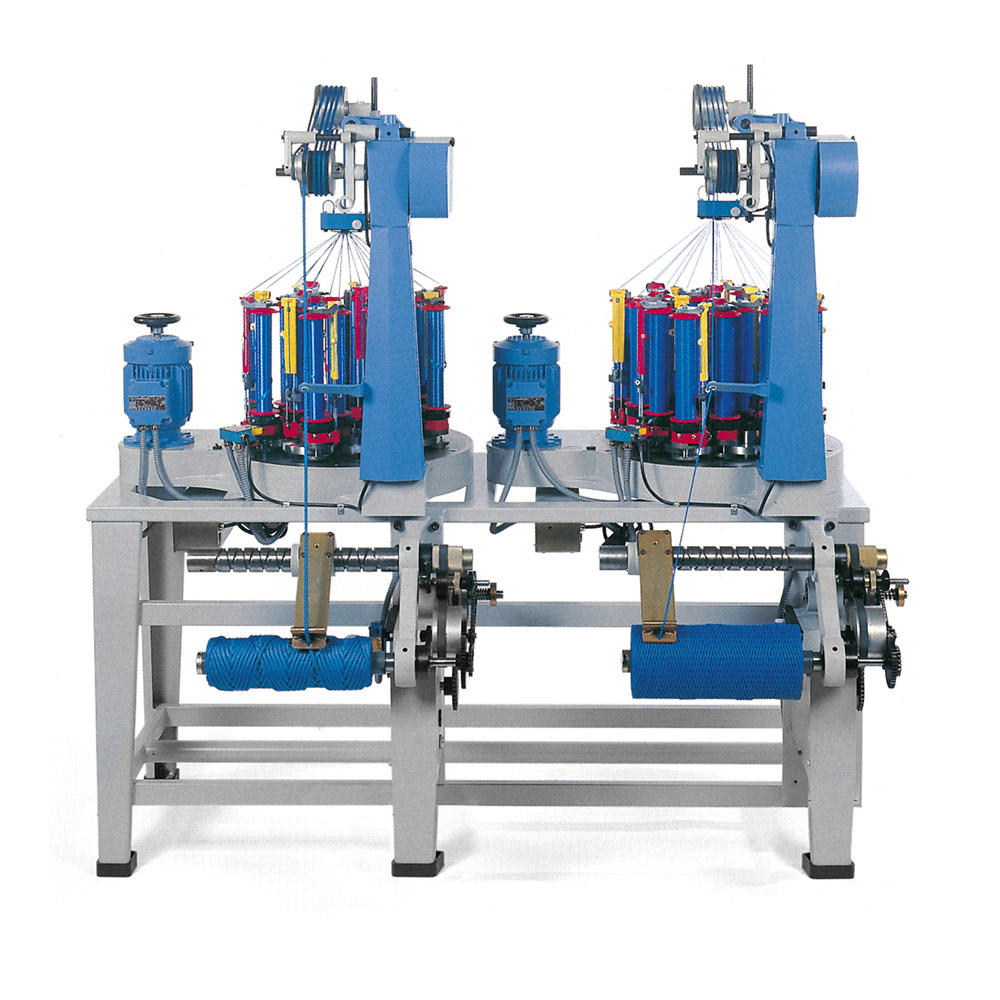

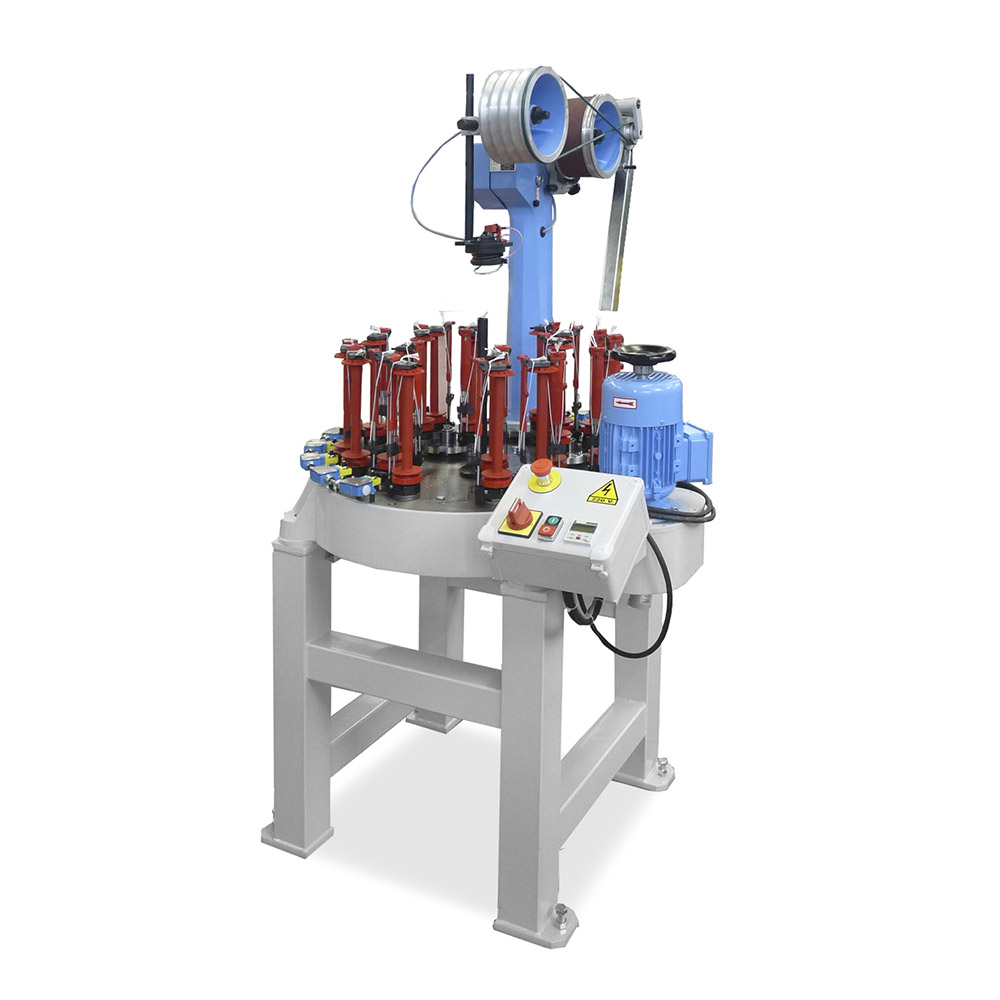

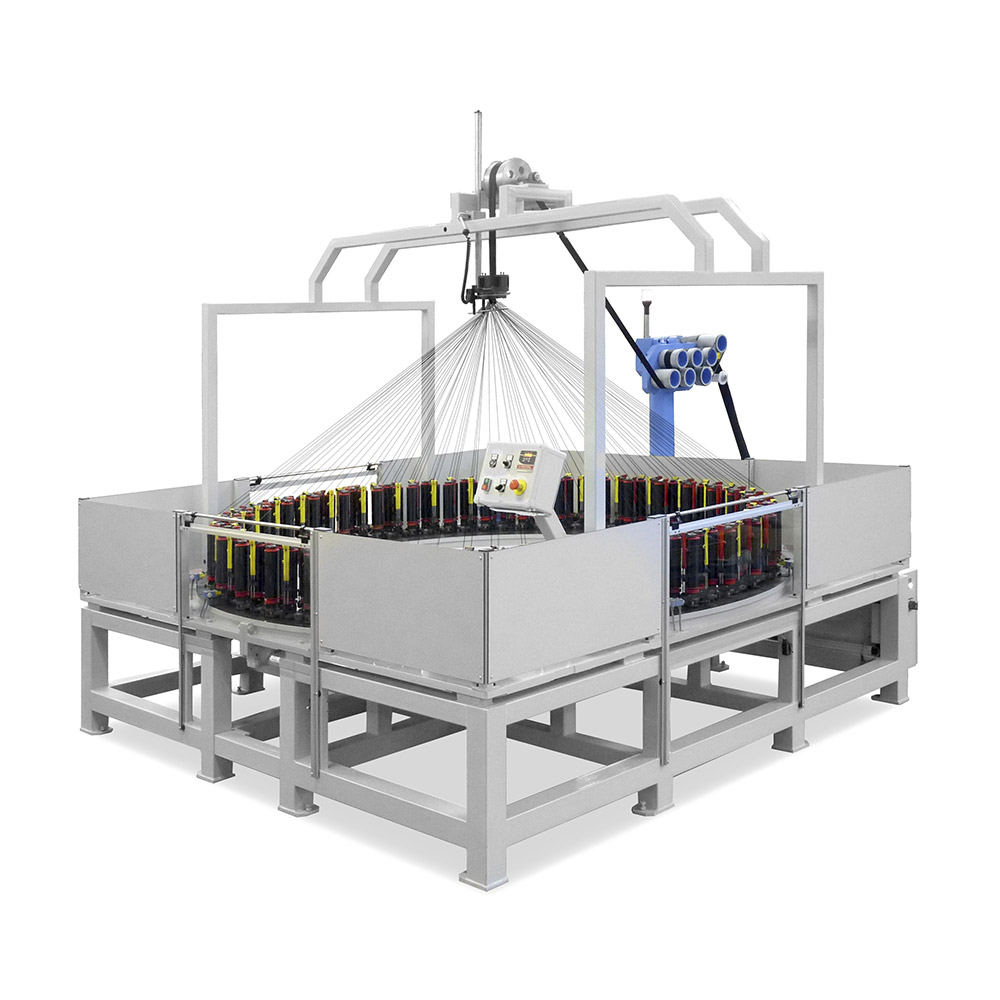

Gauge 115 is for producing braids from 1mm to 50mm in diameter—depending on the number of carriers. Such high versatility and quality are achieved thanks to its robust design (oil bath system in the lower casing and in the take off system)on size, speed and the quality of its materials, as well as an advanced design of carriers, and the possibility of combining different take off systems, carriers, take ups and folding methods.

Gauge 115

Customization and adaptability

A world of accessories

Ratera provides various useful and necessary accessories for the correct production of the desired final product.

- Different types of take ups at the braiding point.

- Different folding systems for the braided product, either on reels of different sizes in a parallel or semi-parallel take up, or on cross take up spools without flanges.

- Different pulling systems depending on the diameter of the product.

Advantages of Gauge 115

Carriers and bobbins Ecartamiento 115

All carriers can be supplied with different versions. Thread guides and tensioners with open hooks or with open or closed ceramics—according to fabric type. Various types of springs with different tensions are available to apply according to each product.

The machines that make up the model 115 can be equipped with three sizes of textile bobbins:

- Ø 63×170 mm with a capacity of 465 cm³.

- Ø 63×200 mm with a capacity of 547 cm³.

- Ø 63×170 mm with a capacity of 465 cm³ (metallic version).

83L System: The most advanced mechanical system

83L System: This advanced mechanical system, originally patented by Ratera, features wear-resistant components made of tempered and ground steel with a medium hardness of 610 Brinell (± 20 points). The carrier feet utilize rotating bushings, and the horn gear cuts are made using plastic segments. The system achieves three significant outcomes:

-

- Increased Production Speed: Boosts production speed by 18% to 25%.

- Minimal Maintenance Costs: Requires little to no maintenance or part replacements in the short or medium term.

- Reduced Noise Level: Significantly lowers noise during operation.

Do you need help?

Ratera, customized machinery.

Videos

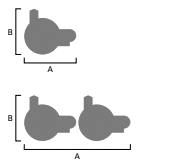

Configurations Gauge 115

| Number of carriers | RPM of the horn gear | Motor power (CV) | Size A x B (mm) | |

| individual | double | |||

| 3 SOU | 300 | 0,33 | 680 x 540 | 1380 x 540 |

| 5 SOU | 300 | 0,33 | 680 x 540 | 1380 x 540 |

| 8* (Ect. 140) | 295 | 0,33 | 680 x 540 | 1380 x 540 |

| 9 | 310 | 0,75 | 860 x 720 | |

| 9 SPI | 300 | 0,50 | 820 x 1060 | |

| 12 | 330 | 0,50 | 700 x 590 | 1385 x 590 |

| 12 SPI | 300 | 0,50 | 820 x 1060 | |

| 13 | 330 | 0,50 | 700 x 590 | 1385 x 590 |

| 16 | 330 | 0,50 | 750 x 650 | 1520 x 650 |

| 17 | 330 | 0,50 | 750 x 650 | 1520 x 650 |

| 18 SPI | 230 | 0,75 | 940 x 1120 | |

| 20 | 310 | 0,75 | 860 x 720 | – |

| 20 SPI | 230 | 0,75 | 940 x 1120 | |

| 21 | 310 | 0,75 | 860 x 720 | – |

| 24 | 310 | 0,75 | 890 x 810 | – |

| 25 | 310 | 0,75 | 890 x 810 | |

| 28 | 310 | 0,75 | 990 x 900 | – |

| 29 | 310 | 0,75 | 990 x 900 | – |

| 32 | 290 | 1 | 930 x 1070 | – |

| 32 HORIZ | 254 | 1 | 1880 x 1400 | |

| 33 | 290 | 1 | 930 x 1070 | |

| 36 | 290 | 1 | 1000 x 1120 | – |

| 40 | 270 | 1,5 | 1160 x 1250 | – |

| 44 | 270 | 1,5 | 1130 x 1250 | – |

| 48 | 270 | 2 | 1160 x 1250 | – |

| 48 HORIZ | 230 | 2,25 (3 mot) | 1630 x 2260 | |

| 52 | 260 | 3 | 1450 x 1615 | |

| 56 | 260 | 3 | 1500 x 1750 | – |

| 60 | 260 | 3 | 1900 x 2000 | – |

| 64 | 260 | 3 | 1750 x 1900 | – |

| 64 HORIZ | 240 | 3 | 2180 x 2280 | |

| 68 | 260 | 3 | 1720 x 1870 | – |

| 72 | 230 | 3 | 2100 x 2200 | – |

| 80 | 230 | 3 | 1935 x 2075 | – |

| 96 | 230 | 3 | 2400 x 2500 | – |

| 120 | 230 | 4 x 1 | 2500 x 2900 | – |

| 144 | 220 | 4 x 1 | 3400 x 3000 | – |

(RPM depending on fibers)

* Bigger horngear

SOU – Soutache

SPI – spiroide

HORIZ – Horizontal Braider