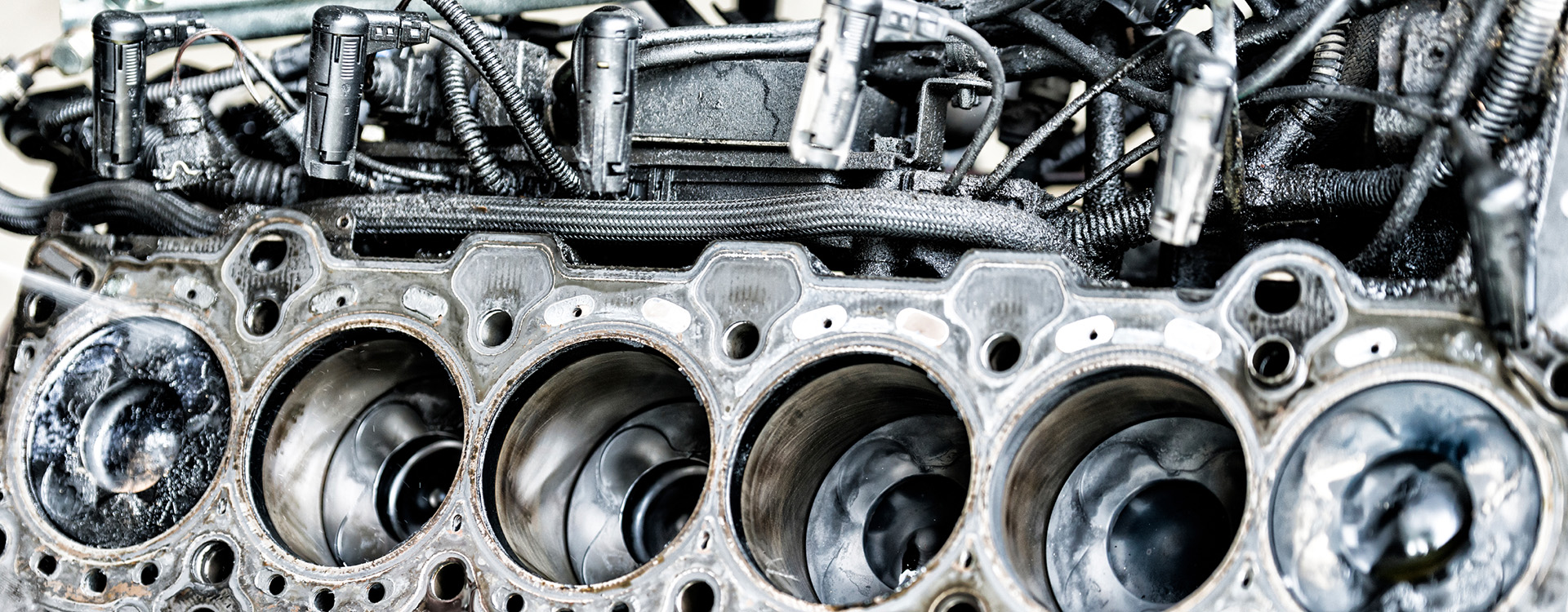

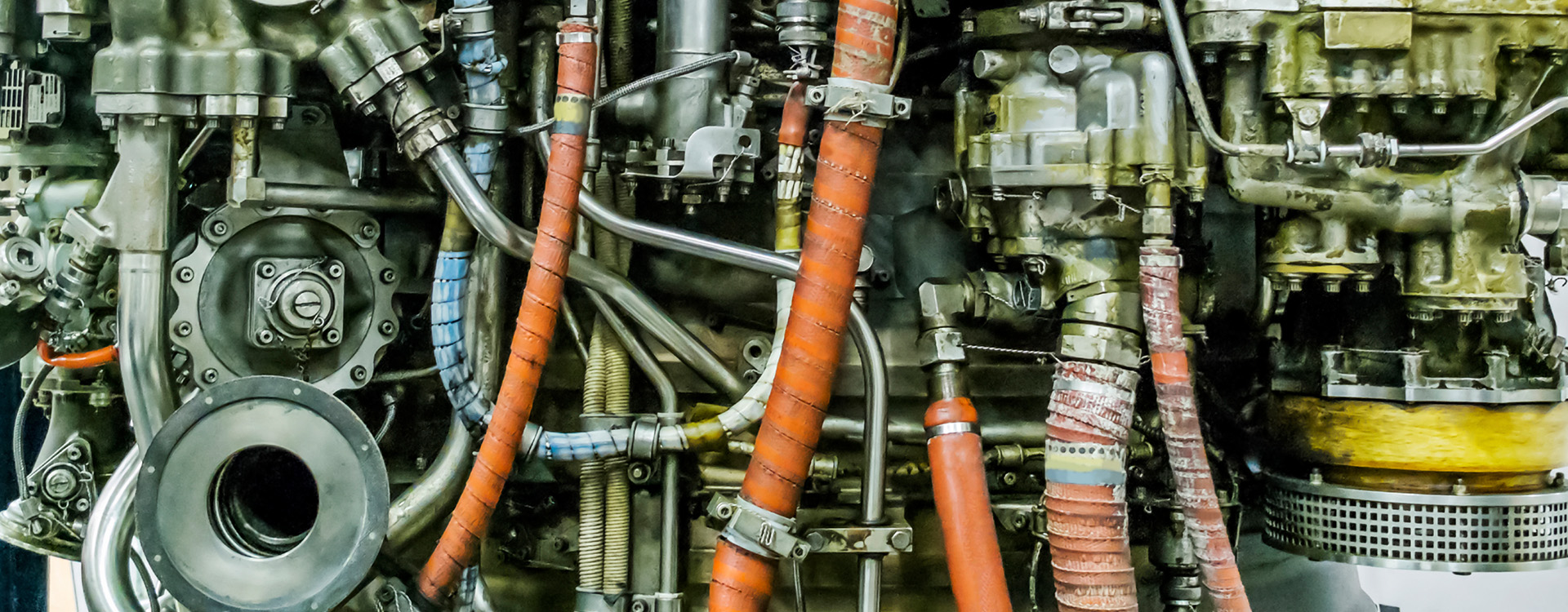

Covers

Applications

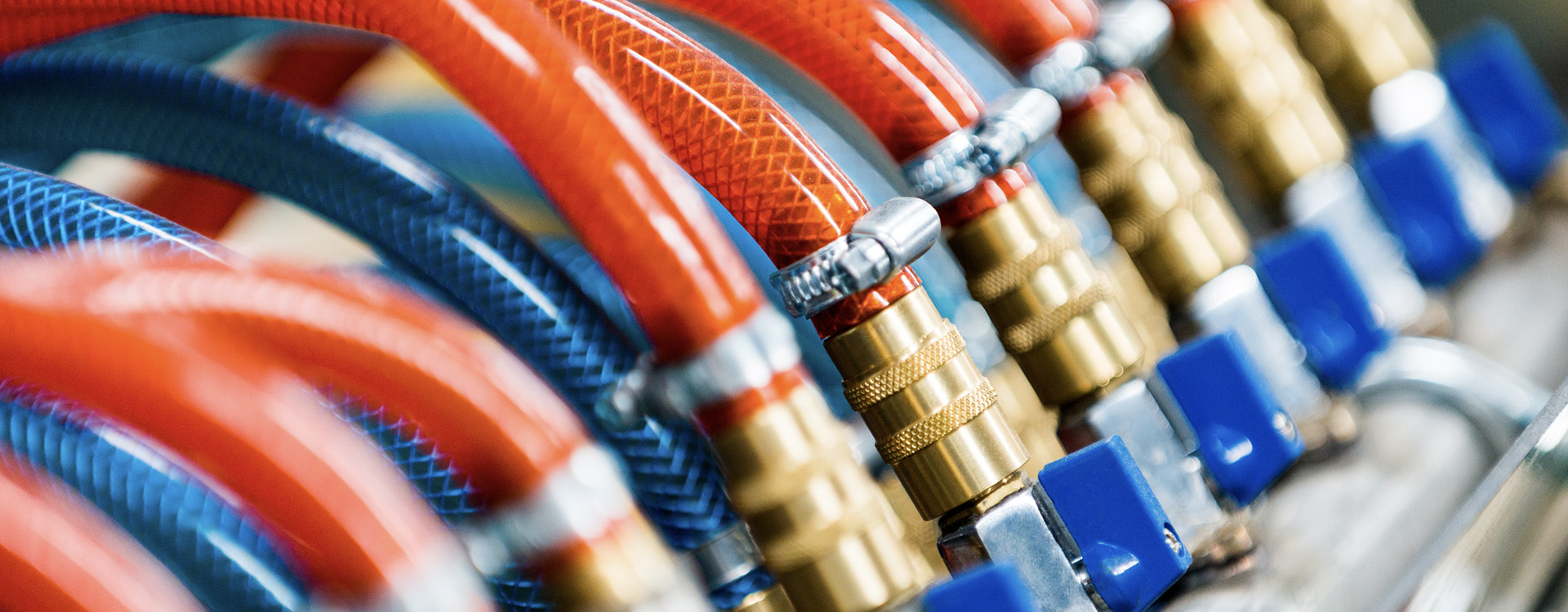

- Braided hose

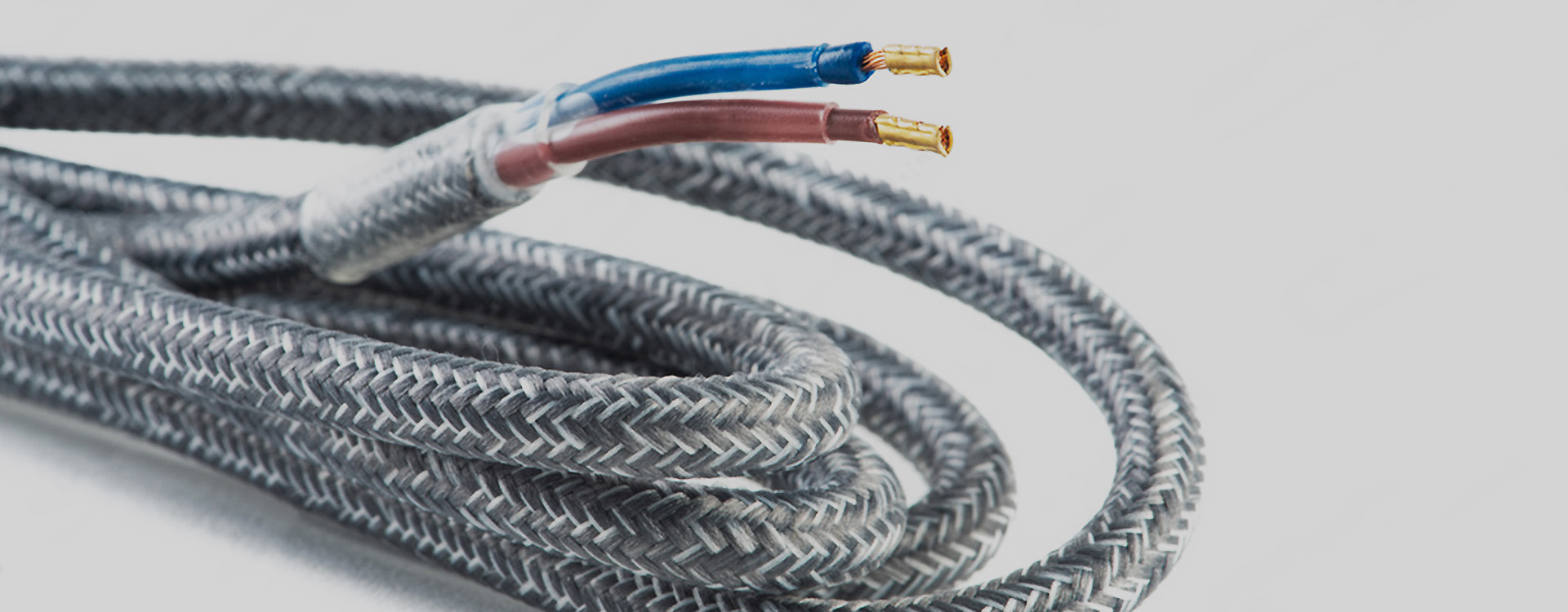

- Coating for electric cable

- Textile coating

- Iron cable

Materials

- Polypropilene

- Polyetilene

- Fiberglass

- Monofilament

- Multifilament

- Aramid

We customize our product depending on your needs

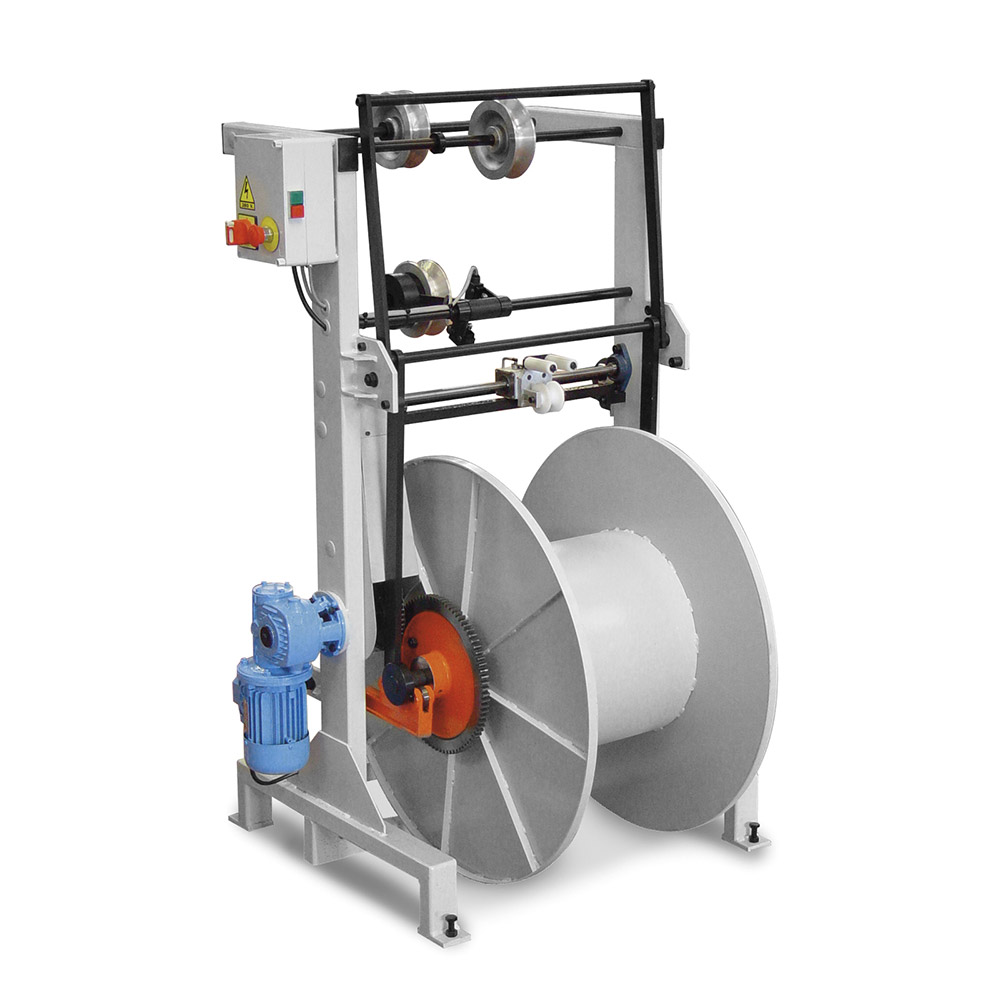

Some of the important features of the braiding machines are:

- Number of Carriers: The number of carriers depends on the size of the core to be covered. Larger cores require more carriers to ensure complete coverage. For instance, to cover thin cables, 16 or 24 carriers may be enough, but for wider corrugated tubes, 32, 48, or even more carriers might be needed.

- Gauge: The choice of spacing (Gauge) in millimeters between the horn gears depends on the type of material you intend to work with. For materials like fiberglass, ceramic fibers, or very fine threads, E80 and E104 spacings offer better-finished product quality. For thicker polyester monofilaments with multiple threads per bobbin, E115 offers an excellent performance.

- Traction System: Ratera offers different systems to drive the braiding, such as wheels driven by a point braid collector or multiple wheels.

- Accessories: These can include an anti-tangling switch at the braiding point, core control, traffic light system, and meter counter.

- Safety : The machines are equipped with safety features that comply with CE and/or national standards in each country

Please do not hesitate to contact us if you require assistance in defining the right machine for your specific needs.