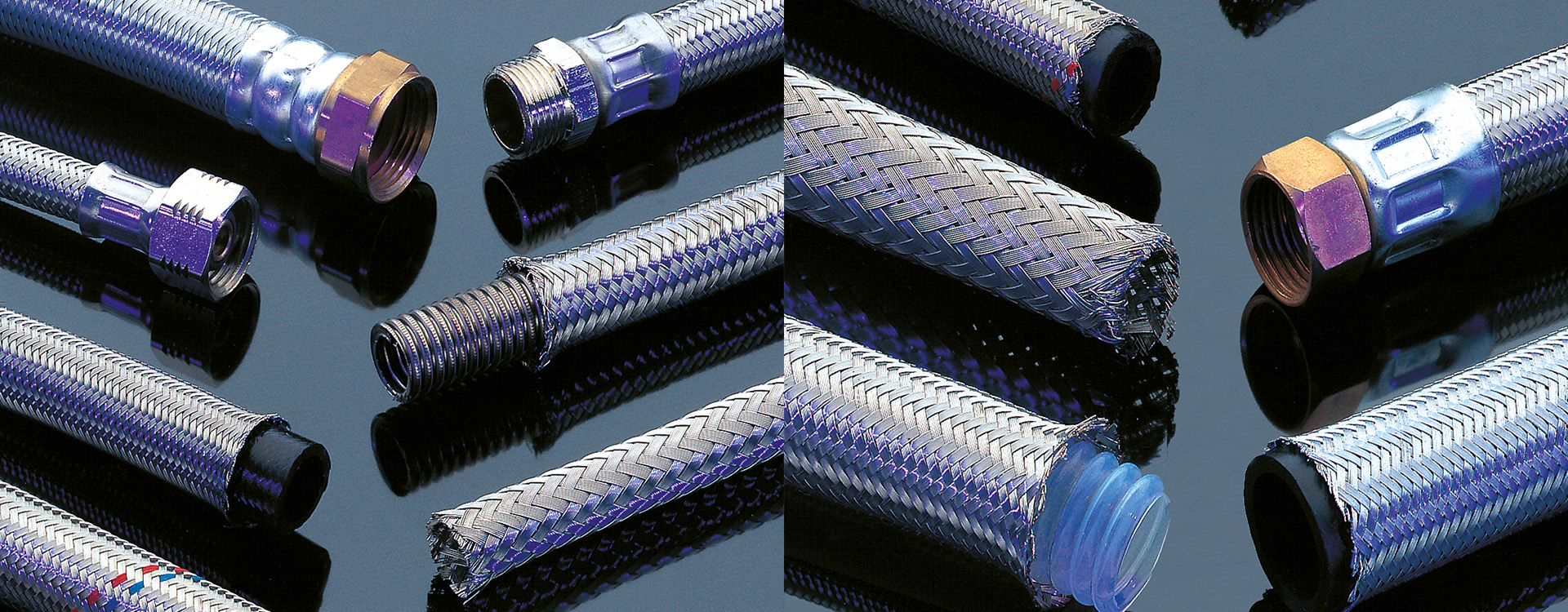

Fluid Conductors

Ratera braiding machines provide a metallic coating for conduits used in hydraulic applications. The braiding strengthens the pipe against pressure, offers increased resistance to impacts or external forces, and maintains a significant degree of flexibility.

Applications

- Hydraulic hose

- Pipe coatings

- Sanitary hose

- Metàlic braids

- Brake hose

- Oil hose

- Exhaust pipes

Materials

- Copper

- Aluminum

- Tin

- Stainless steel

- Gold & Silver

- Magnesium wire

We customize our machines depending on your needs

Ratera offers solutions in metallic braiding. Some of the solutions are:

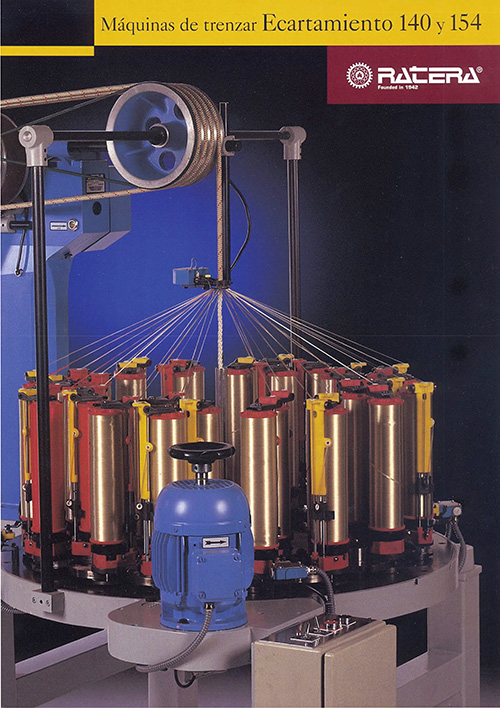

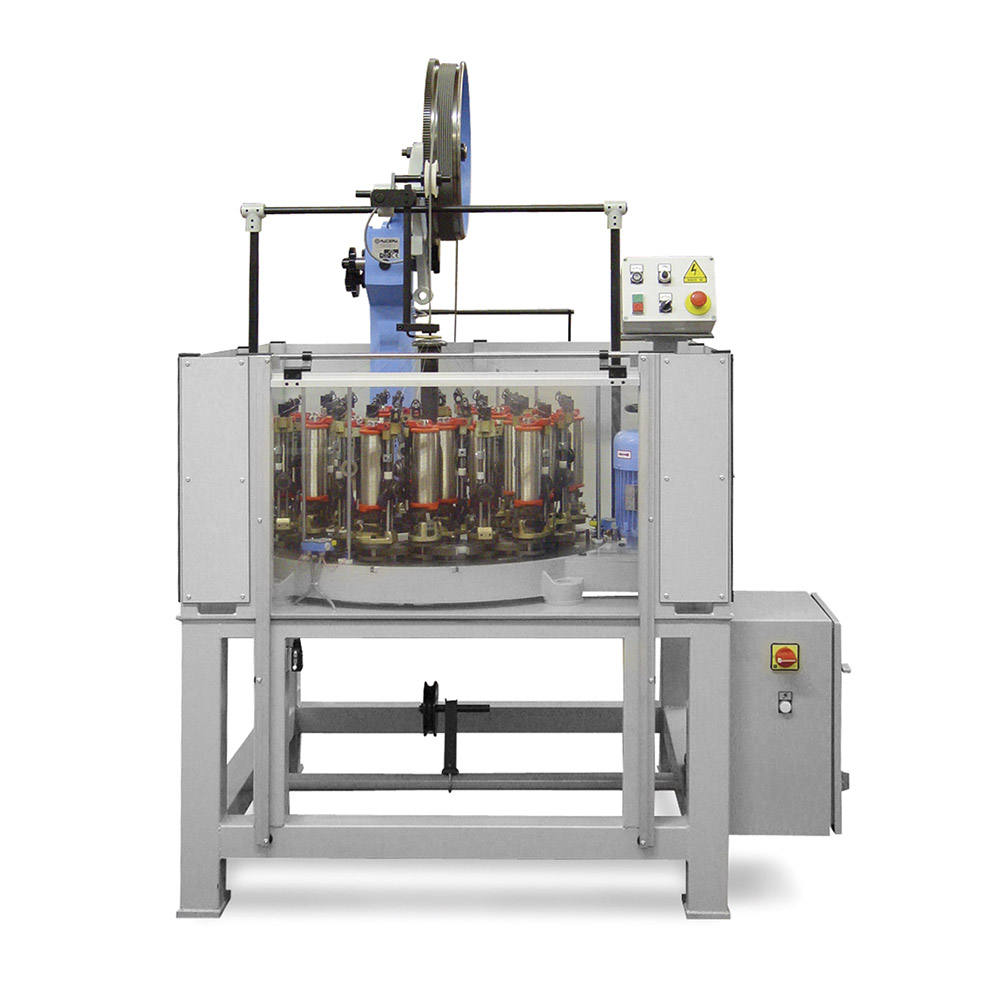

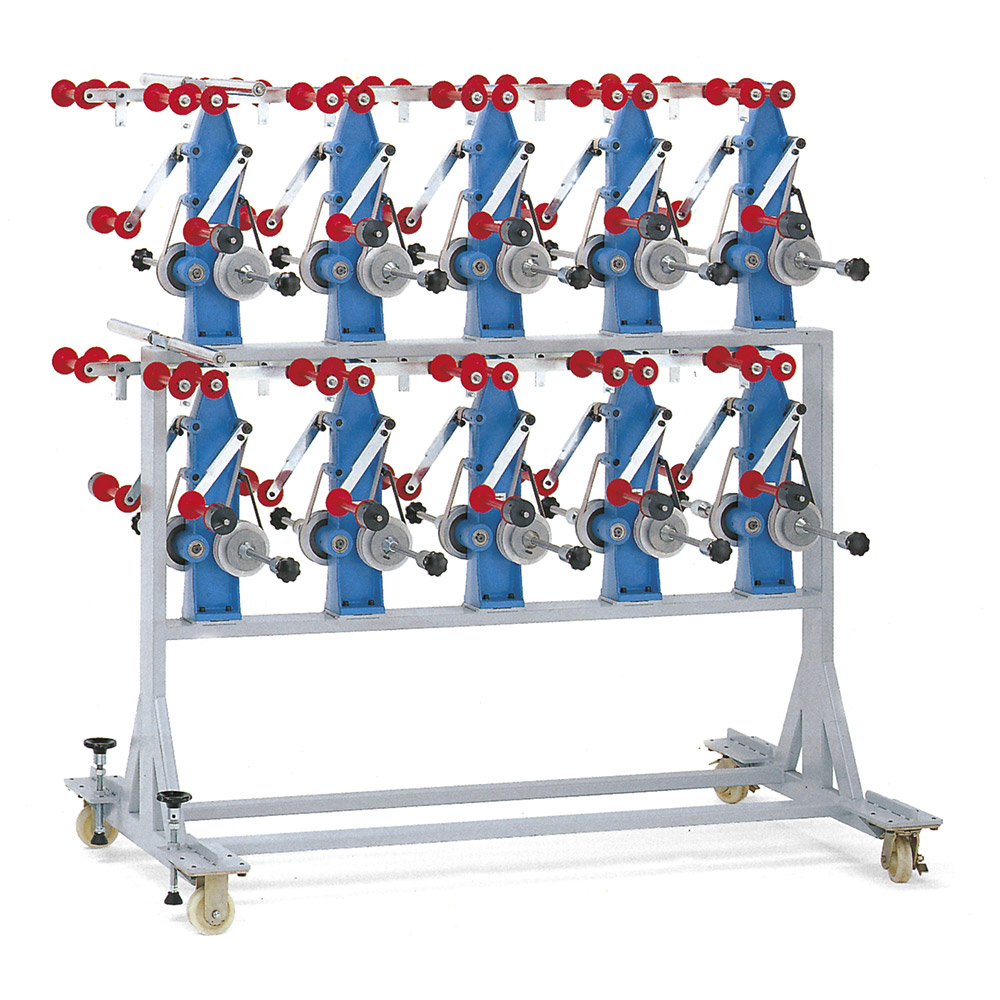

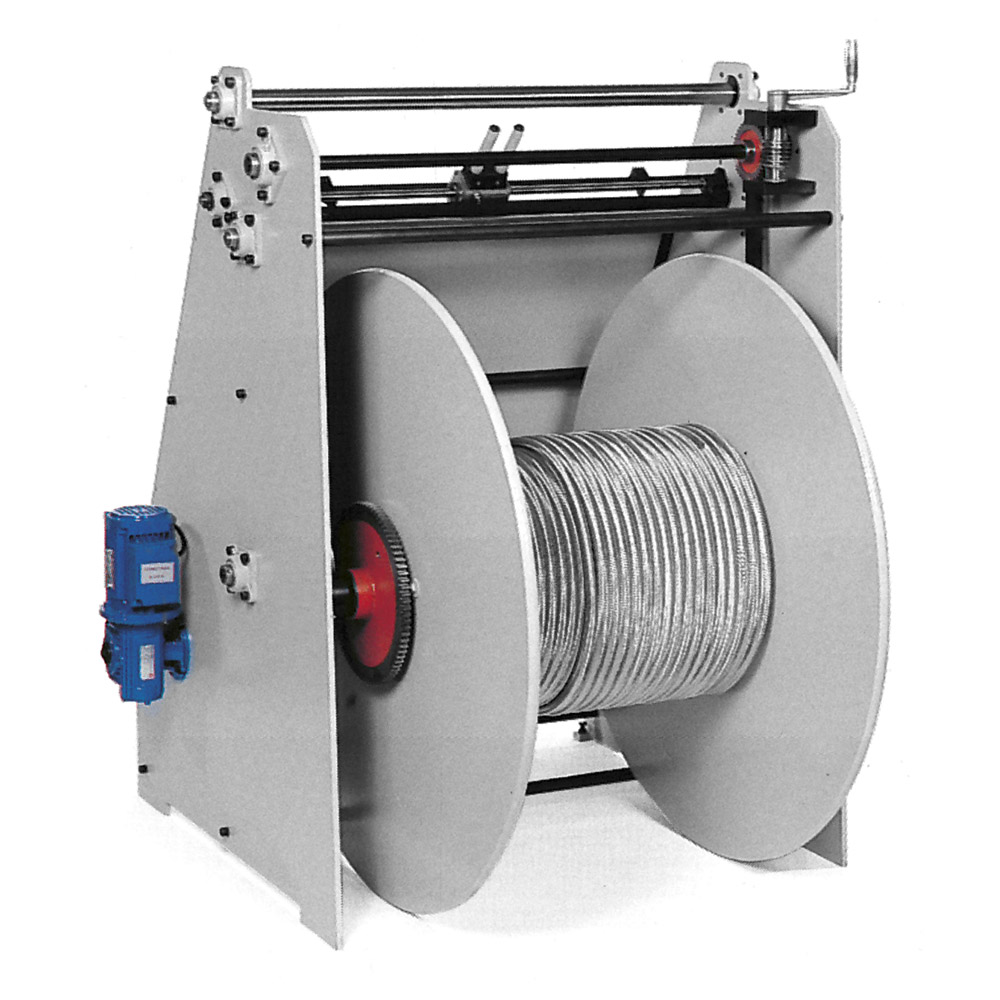

- Number of carriers: The carrier is the mobile element where the bobbin with the wire to be braided is loaded. In hydraulic hoses, constructions of 24 and 48 are popular.

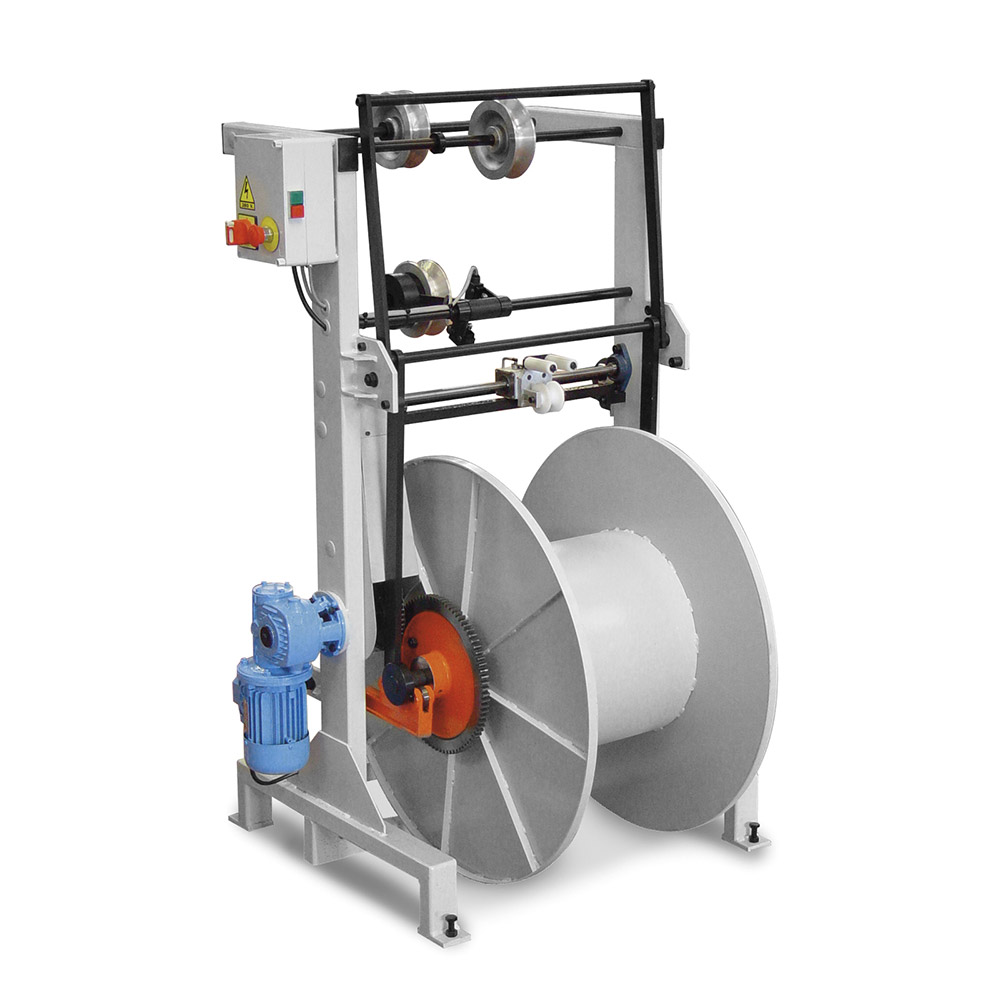

- Gauge: Directly related to the bobbin capacity, Ratera offers 3 metallic models: E104, E115, and E154. The E154 allows working with very thick metallic wires and the E104 with finer wires. The E115, in between, offers a good speed-quality ratio.

- Horizontal Braiders: For large diameter hoses or those with little flexibility, a caterpillar hauling system is used that works synchronously with the braider.

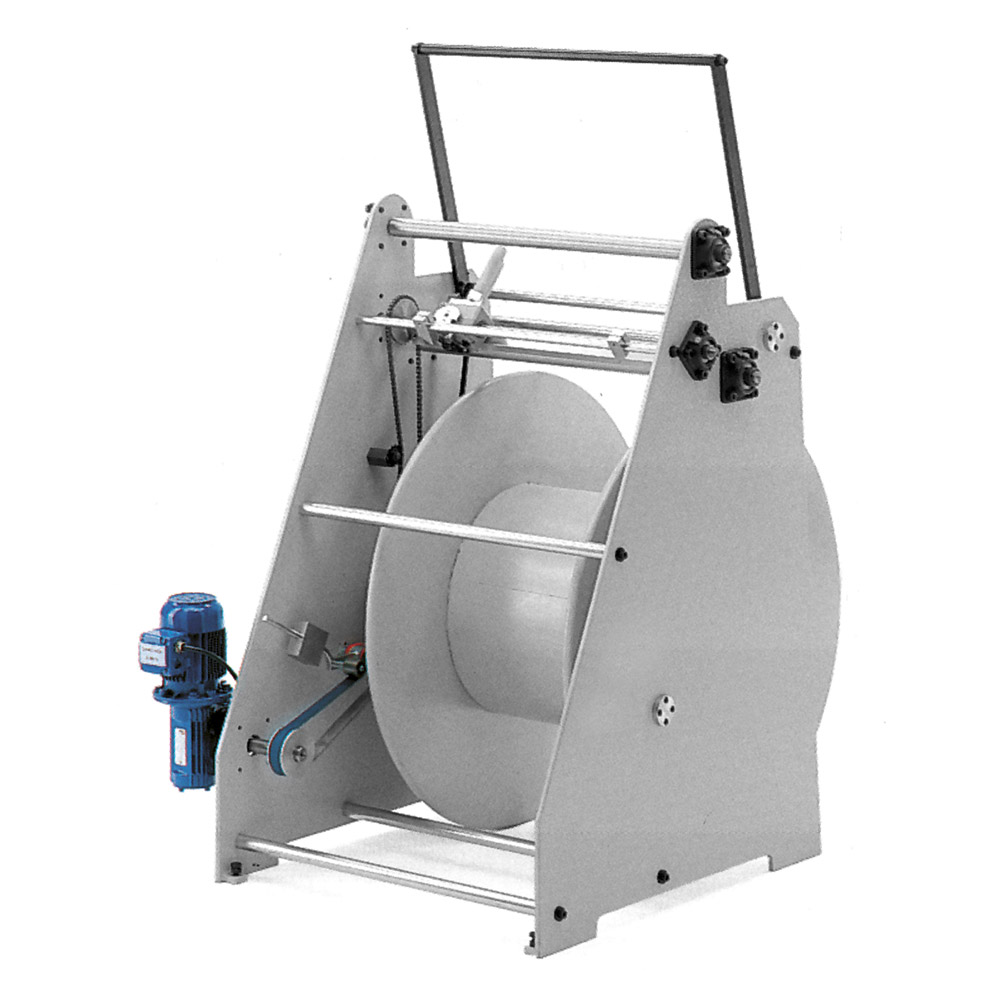

- Vertical Braiders: For space optimization, working comfort, and maximum speed, the vertical braider is ideal. Generally, it works with a wheel with a folder.

Do not hesitate to contact us for support in defining your machine.