At Ratera, we design and manufacture a wide range of braiding machines, capable of producing various braiding structures tailored to different industries. Braiding constructions generally fall into two main categories: flat and round, with specialty braids serving niche markets and applications.

Braiding Machine Construction Types: Flat, Round & Specialty

Flat Braids (Flat Braiding Construction)

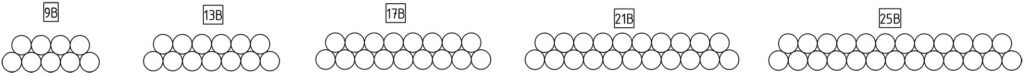

Flat braids consist of carriers, also called spindles, moving in the same direction, resulting in a flat structure. They are non-extendable, though elastic braids can be created by integrating rubber or flexible materials. These braids are built using an odd number of spindles, starting from 9 and going up in increments of four (e.g., 9, 13, 17, up to 121 spindles).

Thickness vs. Width: The thickness of the flat braid is determined mainly by the size of the threads used, while the width is influenced by both the thread size and the number of spindles. As the spindle count increases, the width of the braid grows, making it suitable for a variety of applications, such as straps, decorative tapes, and laces.

Video: 17-Spindle Flat Braiding – Slow Motion

… up to 121

Simplified illustration of flat braid constructions

Let's see some examples of flat braids:

Rigid Flat Braid (without cores)

Rigid flat constructions basically do not use elastic cores. In fact, if they have some elasticity, it will be due to the yarn itself, but in general, they will be a stable braid, with significant tensile strength, flexibility, and the extra durability that braiding offers.

This type of construction is suitable for various applications, for example, for ligature repair, where the flat shape adapts to the weave, or decorative braids with multiple colors, rigid flat cords, automotive and aeronautical cords, and even grounding braids.

Flat Elastic Braiding (with cores)

Another area of application is flat elastic braiding. For this type of construction, odd-numbered braiding machines are used, where elastic rubber cores are inserted between the braids. The braided thread protects the elastics from external conditions and simultaneously limits expansion, ensuring the longevity of the inner elastics.

A popular example is the straps for medical masks, and we also find elastic braids in various garments in the textile industry, such as elastic bands for bras.

Round Braids (Round Braiding Construction)

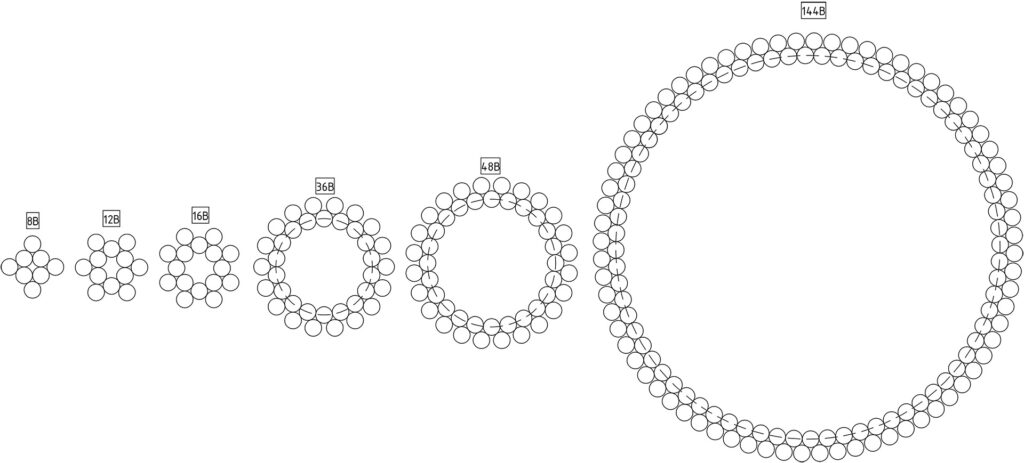

Round braids are circular braids made with an even number of spindles, starting from 8 and increasing in steps of four (e.g., 8, 12, 16, up to 144 spindles). Half of the spindles rotate in one direction, while the other half moves in the opposite direction, crossing each other and forming a strong circular braid.

The number of applications and constructions here is vast and diverse. Below, they are classified depending on core presence or not, and mentioning some applications of them.

As the number of spindles increases, more space is created in the center of the braid, allowing for the inclusion of a core if the application require it.

Video: 16-Spindle Circular Braiding – Slow Motion

Simplified illustration of round braided constructions

Let’s separate the round braids in 2 categories, depending on if core is used or not.

Hollow Braids (No Core)

Hollow braids, also referred to as tubular braids, are characterized by the absence of a core, leaving a hollow center. Key points about hollow braids. They are common in both low and high spindle counts. For instance:

8 or 12 spindles: These hollow braids have limited space inside, leaving almost no space for a core introduction. Generally, the braiding angles are pretty steep (lower than 45º compared with the axial direction) and the braid itself provides high resistance against tensile forces. It is important to consider the fiber torsion when braiding to optimize product performance. Examples of applications include fishing lines, mooring ropes, or fine surgical sutures.

Higher spindle counts without core (e.g., 32, 36, 40): The increased number of spindles leaves more space in the center. In some cases, the braid is flattened to create products like shoelaces, which have a tubular but flat structure. Shoelace is just an example, but there are also orthopedics applications or sleeving solutions under these number of carriers.

Large hollow braids (e.g., 48, 72, 144): With high spindle counts, these braids offer significant internal space, making them suitable for protective sheaths. Examples include fiberglass and monofilament sleeves for passing wires, copper sheaths for shielding or carbon fiber structures.

Braids with Core (Core-Supported Braids)

Round braids that incorporate a core are used in applications where additional strength or specific functionality is required. Common core types include:

Elastic Core: Used in bungee cords or elastic tie-downs, providing the flexibility and resilience needed for dynamic applications. The braided cover provides extended lifetime to the core rubber, usually more sensible to UV & weather conditions. Parameters such as elongation, strength, durability and Picks per cm precision will require a high-quality braiding machine.

Hose Covering: Braided structures reinforce hoses, such as those used in high-pressure industrial or automotive applications, by providing external protection and increasing pressure properties. The technique of over braiding around conduits can be found in a wide range of applications, for example medical catheters and wire or textile braiding around hose or electrical cables.

Textile Core: On ropes, the braid’s outer layer acts as a sheath, covering a strong textile or synthetic core. This combination provides exceptional strength, abrasion resistance, and a good grip. While the outer braided layer offers protection for the core itself, the core provides resistance against traction. The braiding also ensures the sheath holds tightly to the core, improving performance under stress. Ropes are just an example, but we also fine round braids with core in 16 carrier sutures, round shoelace, small cords, etc…

Specialty Braids

Ratera also specializes in machines capable of producing a variety of unique braids for niche applications:

Solid Cord Braids: Created using spiroid braiding machines, these braids resemble twisted ropes but are, in fact, interlaced. This technique results in a soft, flexible braid with high strength, making it perfect for applications like livestock ropes and starter cords, where contact with the skin is common and a gentle texture is required.

Diamond Braids: The term “diamond braid” refers to braids that form a rhombus pattern, typically achieved using the 2 over 2 braiding construction. This type of braid is common in both round and flat configurations. In flat braiding, machines are specially designed to create this unique pattern.

Indian Braid: In this type of braiding, the carriers hold the bobbins horizontally, making it ideal for braiding flat leather tapes or creating round braided leather loops. This is commonly used for bracelet making and other haberdashery aplications.

Soutache Braiders: These braids are created by spindles moving in a figure-eight pattern, all in the same direction. Soutache braiding machines can incorporate up to two cores and come in different configurations (e.g., 3, 5, 7, 9, up to 21 spindles). They are commonly used in passementerie for decorative trims with vibrant colors, as well as for larger natural fiber braids.

3D Braiding: While most braiding machines are built for continuous production of narrow fabrics, a newer technique has evolved for creating complex composite structures (carbon fiber, aramids, glass fiber, …). This method uses robotic arms or motorized mandrels to braid over specific shapes, forming intricate, non-tubular designs. The braiding table still operates with a large number of carriers, allowing bigger items to be braided. This advanced process is ideal for producing customized, non-linear forms for applications in industries such as aerospace and automotive. Horizontal braiders are commonly used here for easier acessibility. Additionally, a popular concept within this industry is the Triaxial braiding, that consist on adding axial cores (they run in pararlel to the braid direction) interlaced withing the braided structure. This is achieved with drilled horngear and can be applied to both flat and round braiders.

Conclusion

Ratera braiding machines are designed to meet diverse industrial needs, from flat and round braids to specialized braids like solid cord and soutache. Whether it’s strength, flexibility, or a decorative finish, we provide high-quality solutions for a wide range of applications.

Whether you need strong climbing ropes or delicate textile embellishments, Ratera machines are built to deliver reliable performance across all braiding constructions.