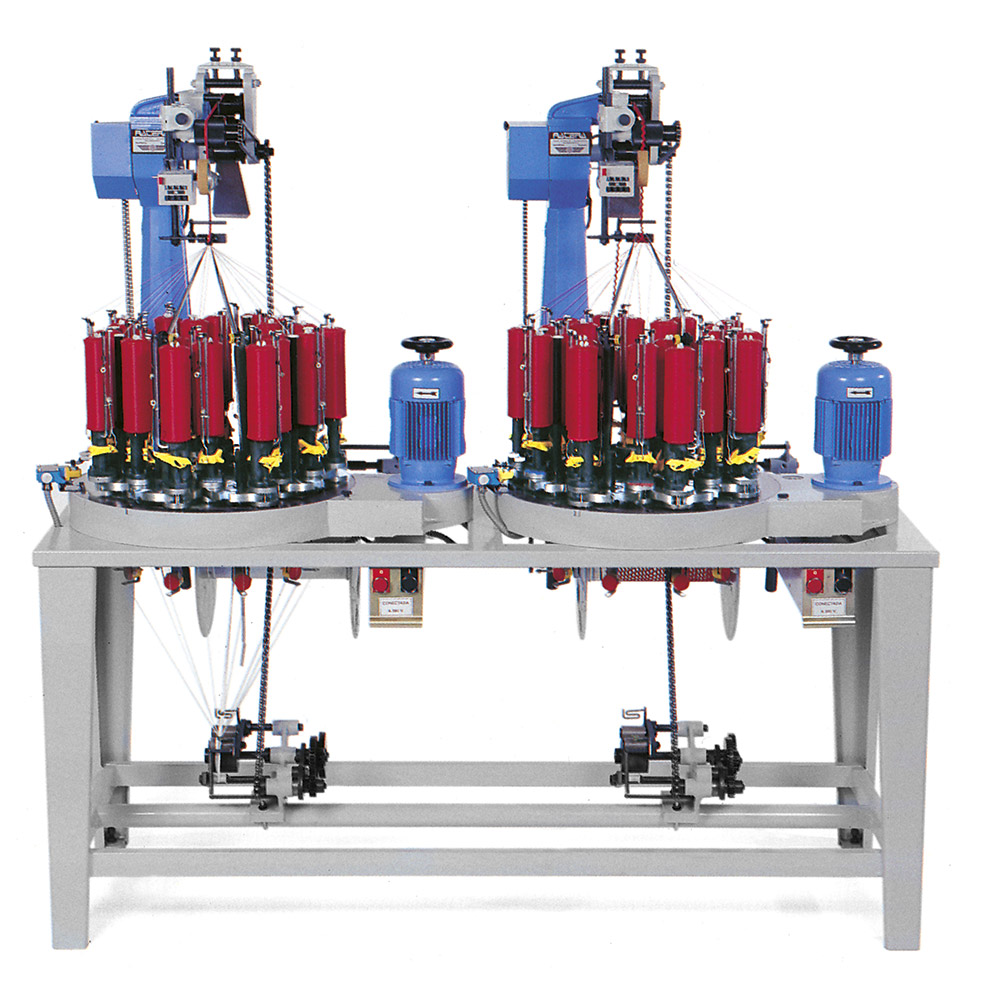

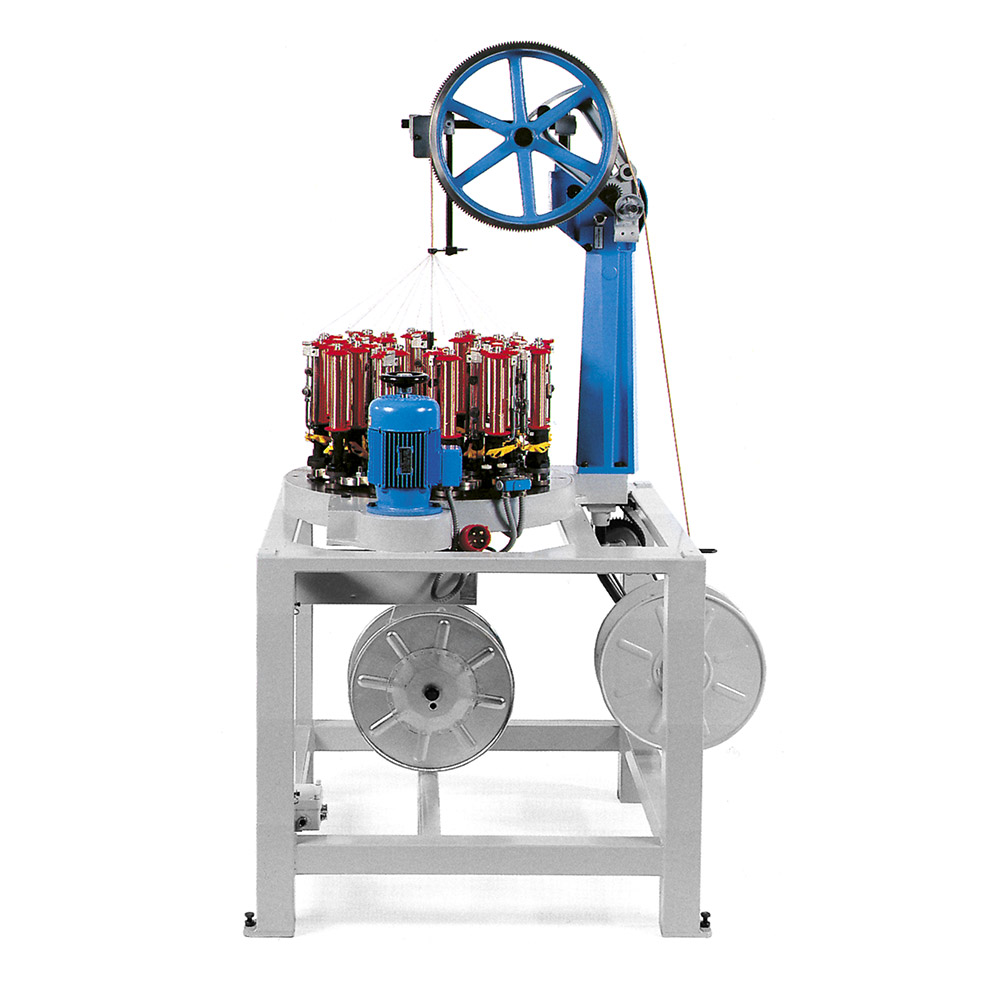

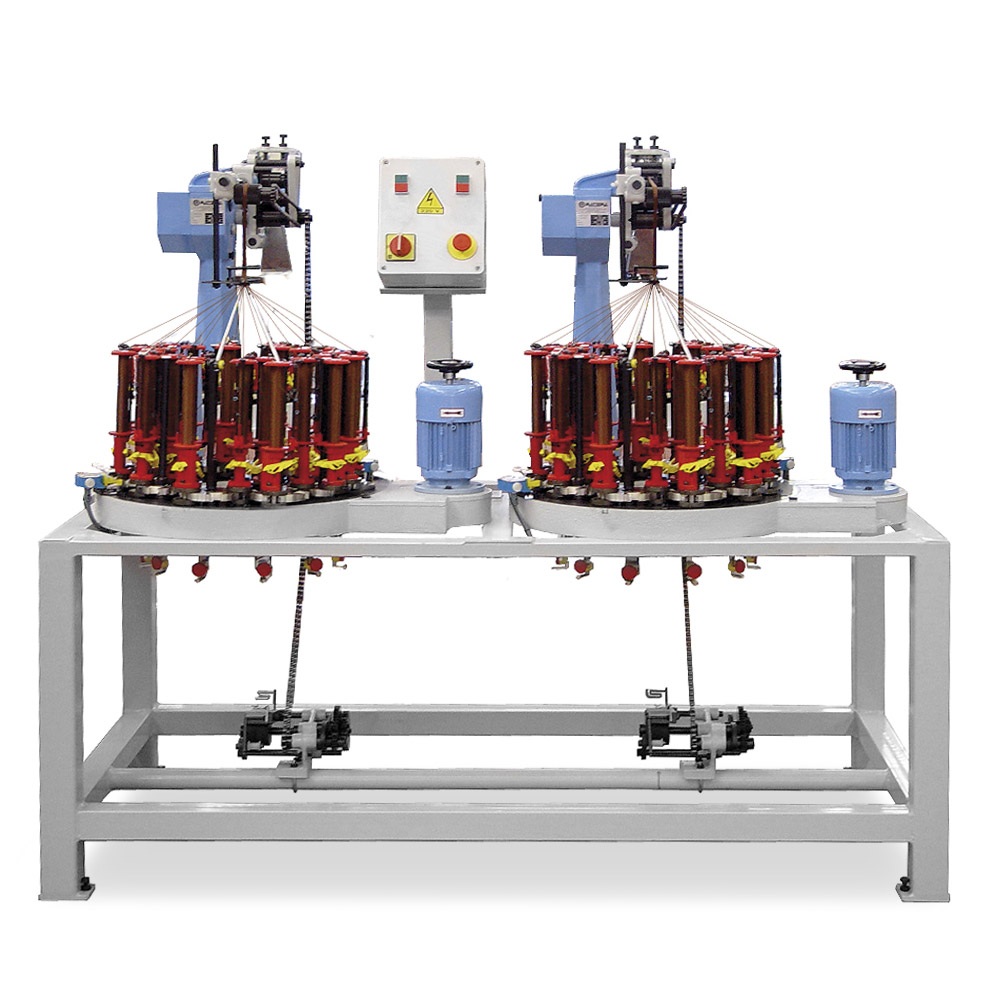

The range of Gauge 104 starts at 8 carriers and reaches up to 120, increasing by 4 each time. Naturally, the odd number of carriers corresponds to machines intended for the production of rigid or elastic flat braids, while the even numbers correspond to the production of round braids and tubular braids, with or without core.

Gauge 104

Customization and adaptability

A world of accessories

Ratera provides various useful and necessary accessories for the correct production of the desired final product.

- Different take ups at the braiding point.

- Different lengths and shapes of needles for obtaining perfect edges of flat ribbons.

- Single or tension-controlled stopping devices for the control of cores.

- For elastic braids, a tension regulation device called “Ratex,” which, through an optimal combination of gears, achieves the desired rubber tension.

- For round braids with or without core, and tubular braids, Ratera has various take ups systems, either on reels of different sizes in a parallel take up of the braided product, or on reels of different sizes in a parallel or semi-parallel take up, on cross take up without a bobbin, or on spoolers.

- Different take off systems. For example, a flat product braiding machine for flat products, a wheel braiding machine for the manufacture of fiberglass sleeves, etc.

Advantages of Gauge 104

83L System: The most advanced mechanical system

83L System: This advanced mechanical system, originally patented by Ratera, features wear-resistant components made of tempered and ground steel with a medium hardness of 610 Brinell (± 20 points). The spindle feet utilize rotating bushings, and the blade cuts are made using plastic segments. The system achieves three significant outcomes:

-

- Increased Production Speed: Boosts production speed by 18% to 25%.

- Minimal Maintenance Costs: Requires little to no maintenance or part replacements in the short or medium term.

- Reduced Noise Level: Significantly lowers noise during operation.

Do you need help?

Ratera, customized machinery.

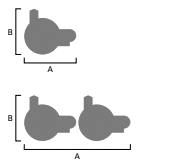

Configurations Gauge 104

| Number of carriers | RPM of the horn gear | Motor power (CV) | Size A x B (mm) | |

| individual | double | |||

| 3 SOU | 300 | 0,25 | – | – |

| 8 | 285 | 0,25 | 560 x 505 | 1115 x 505 |

| 12 | 285 | 0,33 | 610 x 505 | 1220 x 505 |

| 13 | 254 | 0,33 | 680 x 540 | 1360 x 540 |

| 16 | 285 | 0,33 | 700 x 610 | 1400 x 610 |

| 17 | 254 | 0,33 | 700 x 610 | 1400 x 610 |

| 20 | 285 | 0,50 | 785 x 660 | 1570 x 660 |

| 21 | 280 | 0,50 | 785 x 660 | 1570 x 660 |

| 24 | 285 | 0,50 | 860 x 660 | 1720 x 740 |

| 25 | 280 | 0,50 | 860 x 660 | 1720 x 740 |

| 28 | 285 | 0,50 | 870 x 870 | – |

| 29 | 280 | 0,50 | 870 x 870 | – |

| 32 | 285 | 0,75 | 950 x 945 | – |

| 33 | 280 | 0,75 | 950 x 945 | – |

| 36 | 270 | 0,75 | 915 x 1070 | – |

| 37 | 265 | 0,75 | 915 x 1070 | – |

| 40 | 270 | 0,75 | 980 x 1140 | – |

| 41 | 265 | 0,75 | 980 x 1140 | – |

| 44 | 254 | 1 | 1000 x 1140 | – |

| 45 | 260 | 1 | 1000 x 1140 | – |

| 48 | 254 | 1,5 | 1110 x 1240 | – |

| 49 | 260 | 1,5 | 1110 x 1240 | – |

| 72 | 170 | 4 x 0,50 | 1900 x 2100 | – |

| 88 | 170 | 4 x 0,50 | 2000 x 2150 | – |

| 96 | 170 | 4 x 0,50 | 2150 x 2300 | – |

| 100 | 170 | 4 x 0,50 | 2200 x 2300 | – |

| 120 | 170 | 4 x 0,50 | 2500 x 3000 | – |

(RPM depending on fibers)

SOU – Soutache