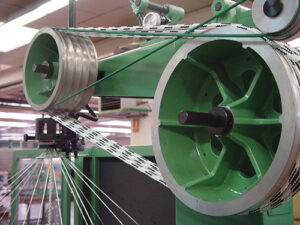

Gauge 240 stands as the larger counterpart to the Gauge 208. With a similar carrier configuration, it boasts a 43% increase in bobbin capacity while upholding comparable levels of speed and product quality. It is used for manufacturing very long braided ropes without splices with a high degree of precision. It allows working with synthetic fibers under several kilograms of tension, whether to produce the core, the cover, or a rope. It is popular among manufacturers of naval and safety ropes.