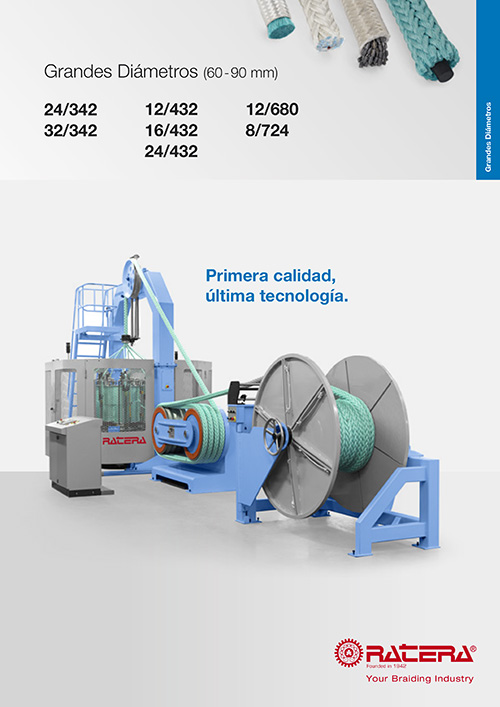

Gauge 342 is Ratera’s first big diameter section. Focused on the production of naval ropes or load-bearing cables, among others, this range of braiding machines is suitable for a wide variety of materials, from nylon and polyester to the most advanced synthetic fibers.

Within this range, we find models designed for manufacturing ropes or rope cores with 8, 12, and 16 carriers, as well as machines with 24 and 32 carriers aimed at making coverings.