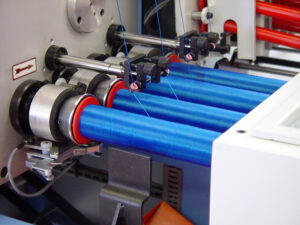

Automatic Winders

Customization y adaptability

A world of accessories

Solutions for all the bobbins

Why choose Ratera?

Durability and Robustness

Manufactured with top-quality materials and thoroughly tested, they enable the handling of the most demanding materials and have a long lifespan with minimal maintenance or spare parts expenses.

Precision and Quality

The precise distribution of the thread maximizes the bobbin capacity.

High speed and Productivity

Ratera manufactures the fastest and most stable winders in the market, enhancing competitiveness from the initial braiding process.

Support and Service

Ratera is the ideal partner, ensuring rapid and long-term spare parts supply, as well as providing training on machinery usage and technical issue support.

Video

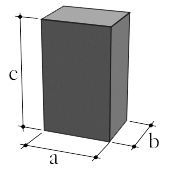

Automatic winders configuration

| NX-100 | BA-4U/140 | ML-100 | |

| Number of carriers | 4 | 4 | 4 |

| System | Uhring | Uhring | Lineal motor |

| Ø Max. per bobbin | From 38 to 80 mm | From 55 to 78 mm | From 38 to 80 mm |

| Run | From 100 to 220 mm | From 170 to 280 mm | From 100 to 220 mm |

| Pitch | From 0 to 5 mm | From 0 to16 mm | From 0,3 to 8 mm |

| Head speed | From 1.000 to 5.300 rpm | From 77 to 3.000 rpm | From 1.000 to 5.300 rpm |

| Yarn maximum speed | 500 m /min | 330 m / min | 500 m / min |

| Motor power | 1,1 Kw | 1,1 Kw | 1,1 Kw |

| Tensioners | 1 | – | 1 |

| Knock off switches | 4 | – | 4 |

| Scissors yarn cut | Yes | Yes | Yes |

| Electrical resistance cut | Yes | Yes | Yes |

| Touch screen | Yes | Yes | Yes |

| Meter counter | Yes | Yes | Yes |

| Layer counter | No | No | Yes |

| Recipe menu | No | No | Yes |

| Multi bobbins | No | No | Yes |

| Lenght (A) | 1.810 mm | 2.400 mm | 1.810 mm |

| Widht (B) | 1.420 mm | 1.800 mm | 1.420 mm |

| Height (C) | 1.800 mm | 1.750 mm | 1.800 mm |

| Weight | 580 Kg | 700 Kg | 580 Kg |

| Customized bobbins | Yes | Yes | Yes |

| Constant yarn speed | Yes | Yes | Yes |

| Knock of switches (maximum) | 8 x bobbin | 10 x bobbin | 8 x bobbin |

| Tension control | Yes 1 yarn x bobbin | Sí 1 yarn x bobbin | Yes 1 yarn x bobbin |

| For suture yarns | Yes | No | Yes |

| For composites fibers | Yes | Yes | Yes |

| Clips feeder assembly | Yes | Yes | Yes |

| Pay off unit | No | No | No |