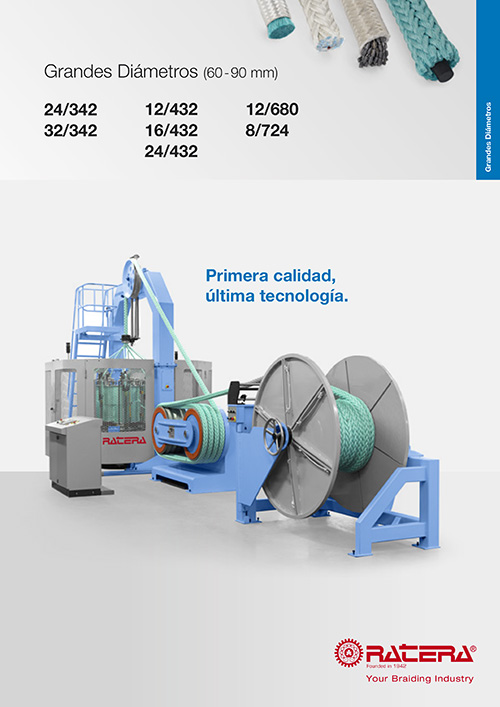

Gauge 680 machines are 2 models available. On one hand, the 8 carrier machine with its patented BackTwist system focused on the production of top-quality square rope. On the other hand, Ratera offers the 12 carrier machine for ropes up to ø 85mm, for example, enabling the production of a 70mm diameter rope with a length of 220 meters without splices.

Gauge 680

Customization and adaptability

A world of accesories

Ratera suministra distintos accesorios útiles y necesarios para la correcta obtención del producto final deseado y adaptarse a las necesidades de cada fabrica. Por ejemplo:

- Back Twist System (patented), which allows for better precision in maintaining the twist of each rope during the braiding operation.

- Compact pulling systems with porch, equipped with a Ø700mm wheel to produce a maximum of Ø70mm or autonomous pulling systems mounted on the ground with Ø800 wheels for making braids up to Ø85mm.

- Metallic ladder for handling the pulling system.

- Different types of anti-tangling switches at the braiding point with the option of a motorized zipper for adjustment.

- Different guides and stoppind devices for the core.

- Integral safety protections for personnel.

- Ratera offers a wide range of take ups for folding the braiding thread, either in Ratera metal bobbins or in synchronized bobbin collectors.

- Ratera offers the possibility of adapting to customer bobbins.

- Customized electrical panel. From the basic panel operated with buttons and basic protections to complete systems with touchscreen, PLCs, speed controls, recipes, and connectivity.

Advantages of Gauge 680

Carriers and Bobbins for Gauge 680

Designed to braid thick threads up to Ø 20mm, this carrier maintains very stable tension control and allows for high-quality braiding of both small and large diameters. Equipped with rollers with lateral bearings and it offers the possibility of customization with a rotating head in the tensioner. Brake system with an adjustable drum. Upper and lower supports with bearings for the bobbin.

Bobbin:

- Ø 365×730 mm. Capacity 74,319 cm³.

83L System: The most advanced mechanical system

83L System: This advanced mechanical system, originally patented by Ratera, features wear-resistant components made of tempered and ground steel with a medium hardness of 610 Brinell (± 20 points). The spindle feet utilize rotating bushings, and the blade cuts are made using plastic segments. The system achieves three significant outcomes:

- Increased Production Speed: Boosts production speed by 18% to 25%

- Minimal Maintenance Costs: Requires little to no maintenance or part replacements in the short or medium term.

- Reduced Noise Level: Significantly lowers noise during operation.

Videos

Configurations of Gauge 680

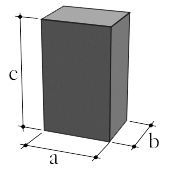

| 680 | 724 | |

| Number of carriers | 12 | 8 |

| Bobbin size | Ø 365 x 730 mm | Ø 335 x 730 mm |

| Bobbin capacity | 74.319 cm³ | 62.280 cm³ |

| Horngear speed | 33 rpm | 24 rpm |

| Carrier speed | 11 rpm | 12 rpm |

| Motor power | 7,5 cv | 7,5 cv |

| Lenght (A) | 7.500 mm | 4.512 mm |

| Width (B) | 3.300 mm | 2.444 mm |

| Height (C) | 5.200 mm | 5.078 mm |

| Weight | 9.250 Kg | 6.635 Kg |

| Maximum Ø | 85 mm | 60 mm |

(RPM depending on fibers)